Flow control for floating LNG

Improving reliability and productivity of your process

Many industrial companies are actively developing floating LNG production. The first commercial floating plants are commissioned and it is forecasted that several more such vessels will be in operation. Valmet's compact and high performance valves and flow control services offer floating LNG plants long lifecycle and trouble-free operations.

Reliability

Expert technical support

Global service reach

Over 65 years of experience in flow control

Reliable flow control and services for floating LNG

Natural gas is a source of energy and an important feedstock in petrochemicals and fertilizers production. LNG is purified and liquefied natural gas (methane) and it is used to produce electricity in gas fired power plants. Natural gas reserves are plenty, but number of large fields, which allow building big capacity on-shore LNG plants (so called base load plants) and related infrastructure in commercially viable manner, is limited. Floating LNG plants make it feasible to develop gas fields, which are too small or are too far offshore to have an onshore plant.

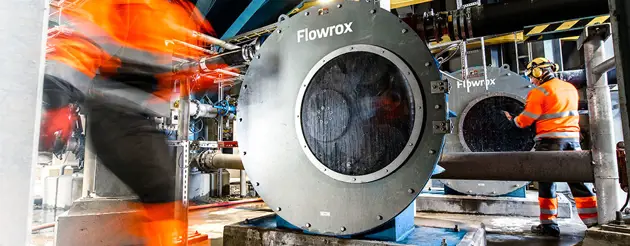

Floating LNG represents new technology. LNG has been produced and transported in commercial scale in onshore plants for over 30 years, so it is not new as such. Producing floating LNG is different and technology to do this has been developed only recently. The main challenges are confined spaces and weight limitations in processing, storing and offloading facilities on a vessel and making the system sloshing resistant. Careful design and construction is needed to maintain safety. The production capacity of a Floating LNG plant is typically 1.0 - 2.0 million tons per annum, while a base load on-shore plant capacity is 3 – 5 million tons per annum.

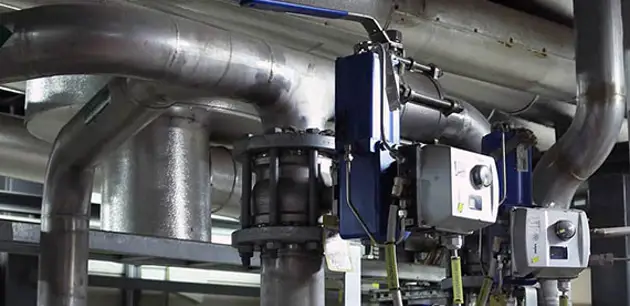

Reliability to floating LNG processing

Our capability to comply with the floating LNG challenges consists of modular, engineered valves for actuated on-off, safety and control valves for the LNG production. Emergency shutdown, blowdown, dryer sequencing valves and flow control applications - we offer a comprehensive line of products specifically selected to overcome the challenges of these applications.

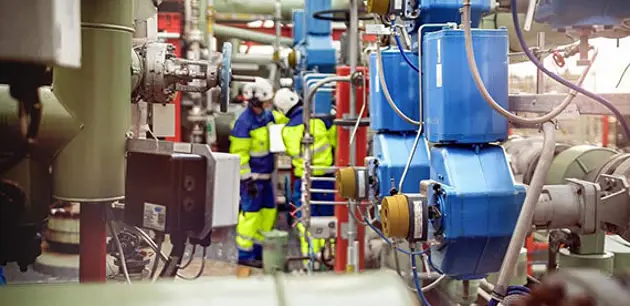

Our philosophy is to partner with customers and provide them engineering support to the whole engineering project cycle from basic and front end engineering to the detail engineering and project commissioning. And when it comes to the moment of servicing the valves, we are there too.

Partnering with customer engineering

We are supporting our customers that are aiming to be the front-runners in producing floating liquefied natural gas (LNG). Early involvement in project design starting from the basic and front end engineering. Competitive, full product portfolio compiled with services to the whole product life cycle.

Flow control and services for floating LNG

Related LNG pages