Flow control for offshore

Improving reliability and productivity of your process

As offshore exploration moves to more remote and hazardous locations, the demand for safe and intelligent flow control systems intensifies. In these harsh environments it’s critical to have equipment that allows operators to continuously monitor the safety and efficiency of the rig. We test every single pump and valve before delivery to ensure quality and safety.

Provide real-time data

to onshore centers to reduce staff needed on board

Identify and fix performance issues

Continuously monitor device health

to develop predictive maintenance plans that focus efforts only on the equipment that needs service, reducing cost and inventory needed on board

Network redundancy and fail-safe systems

including short circuit protection and Emergency Shutdown Valves keep the the rig and staff safe

Common challenges

In an environment where safety and environmental protection are as critical as profitability and performance, operators are challenged to find the right mix of technologies to help them achieve both safety and profitability. Efficiency of processes within oil and offshore industries is based on the quality equipment. It is essential that every piece of equipment is durable, reliable and safe. Therefore, flow control for oil and offshore equipment (pumps and valves) have to be designed to withstand harsh conditions involving abrasion and demanding process mediums.

Reliable flow control for offshore processing

For today’s operators, process awareness is the central challenge because data is the key to overcoming all the most persistent challenges: safety, efficiency, maintenance, and staffing on the rig.

Without intelligent valve controls and diagnostics, the best case is diminished process efficiency, the worst case is that dangerous conditions can go unnoticed and unrepaired. Either condition is unacceptable and will result in additional cost to the operator. Without intelligent valve controls rigs will spend more time and money on maintenance and be required to keep more parts inventory and staff on board.

Robust solutions for oil and offshore reduce risks and save money

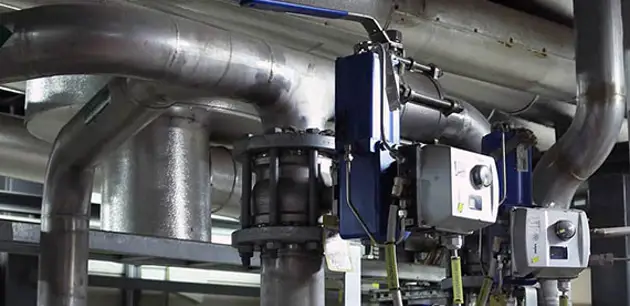

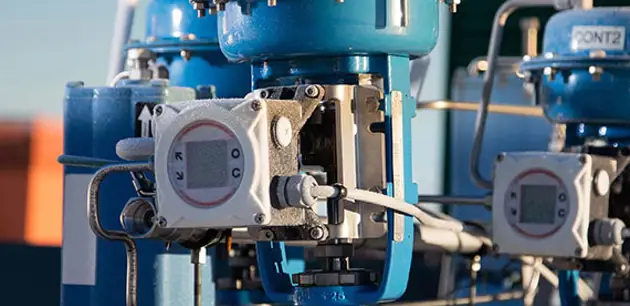

Valmet has developed a series of automated valve packages and controls specifically designed for a life at sea. Built to explosion-proof standards these products also resist the impact of salt and water resulting from high seas and heavy wash-downs.

In addition, our Flowrox™ heavy duty pinch valves and pumps represent process reliability, low maintenance costs, long service intervals and are safe to operate. Peristaltic pumps, flow control and shut of valves are built to last in the harshest environments. Elastomer hose or sleeve inside the pump or valve is the only part in contact with the medium. This importantly limits the wear and reduces maintenance time and costs as it is easy to replace on site. On top of that, rubber hose or sleeve is naturally wear and abrasion resistant.

Intelligent valve controls make the difference

On top of the most reliable hardware, our intelligent valve controls give operators unparalleled awareness and control of their processes. The result is that rigs operate more efficiently over longer periods of time and at a lower cost. This is achieved by allowing operators to optimize devices and monitor equipment to proactively resolve problems and deploy a preventative maintenance strategy. Intelligent valve controls from Valmet are the ideal solution for offshore applications, where top class performance, comprehensive diagnostics and resistance to tough environmental conditions make the difference in safety and performance outcomes.

Flow control solutions and services for offshore

Read more about our solutions for gas processing