Beyond Circularity: CEBIPRO project develops innovative analysis technologies for circular economy biorefineries

Apr 12, 2023

Wood pulp brings interesting new opportunities, and new applications can support the forest industry in moving toward the circular economy and the green transition. Pulp and fiber grades like depolymerized cellulose, modified cellulose, and micro- and nano-cellulose fibril materials (MFC*/CNF) can be used as raw materials for textiles, films and liquid packages, for example. However, sufficiently accurate analytical methods remain lacking, and there is insufficient industrial understanding of microfibrils in fibrillation and retention. The CEBIPRO project aims to solve this challenge by developing innovative industrial and online fiber and water analysis technologies for fiber treatment and engineering processes and products.

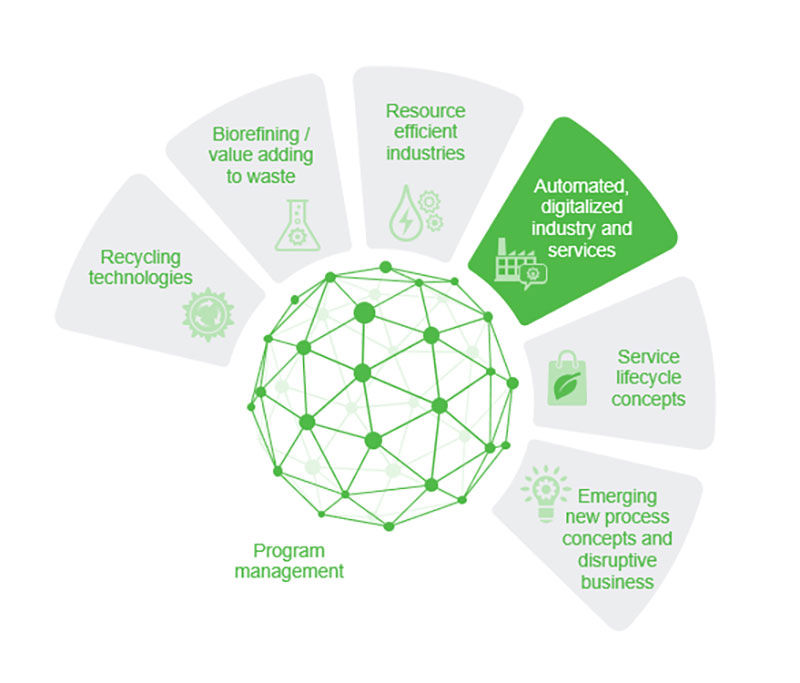

This co-research project is part of Valmet’s Beyond Circularity program, which aims to transform waste and emissions into valuable resources for sustainable growth and to accelerate the green transition. The project is coordinated by Xamk (South-Eastern Finland University of Applied Sciences) and partly funded by Business Finland.

New knowledge, technologies, and competences for fiber ecosystems

“The main objective of the CEBIPRO project is to develop new knowledge, technologies, and competences for fiber ecosystems to optimize processing efficiency and product quality. Xamk has conducted applied research using fractionation and Nuclear Magnetic Resonance (NMR) techniques to characterize MFC, and in the CEBIPRO project, we are deepening this understanding in our FiberLaboratory in cooperation with industry leaders and partners. We are also evaluating the applicability of these characterization techniques to establish an analytical platform for the online monitoring of closed water loop chemical constituents to further the sustainable production of bio-based products,” says Lasse Pulkkinen from Xamk.

Valmet’s special camera technology improves the analysis of new cellulose grade

The project is well aligned with research and the development of analytics and measurement at Valmet.

“At Valmet, we believe that analyzers and measurements are the cornerstones of successful process controls and optimization. We are continuously developing our proven technologies to discover how to respond better to our customers’ needs and support them in the green transition. Valmet’s special camera technology will be utilized in this project to improve the analysis of new cellulose grade and the efficiency of production processes. We have a long and fruitful cooperation with Xamk and are happy to join forces with them in this project as well,” says Päivi Tikkakoski, Director, R&D, Analyzers, Measurements and Performance Solutions at Valmet.

Monitoring critical parameters in pulp and paper mill water streams

Pulp and paper production are very water-intensive industries. Economic and ecological reasons have led mills to close their water cycles and reduce freshwater consumption. “Closing the water loops means an increased amount of inorganic and organic substances in process waters, which may cause severe quality and runnability problems. In the CEBIPRO project, Xamk will study the applicability of novel analytical techniques to monitor critical parameters in pulp and paper mill water streams. This is well aligned with our water-related measurement technology research and development goals,” says Heidi Tervo, Technology Manager, from Valmet’s Analyzers and Measurements R&D.

The project was kicked off in 2022 and will continue until 2025. Its total budget is more than EUR 1.3 million, and the project has been granted NextGenerationEU funding from the EU’s Sustainable Growth Programme for Finland.

*Microfibrillated Cellulose (MFC) is a natural material made of cellulose fibrils that have been separated from a source such as wood pulp.

Valmet Beyond Circularity is implemented through seven streams. The CEBIPRO project is part of Automated, digitalized industry and services stream.

CEBIPRO project in brief

- Target: New analysis technologies for circular economy biorefineries

- Valid: 1.1.2023– 30.4.2025

- Industrial partners: Valmet Oyj, Aquaflow Oy, Wetend Technologies Oy, Fiber-X Finland Oy, Stora Enso Oyj, UPM-Kymmene Oyj

- Project budget: €1,345,714. Partly funded by Business Finland.

- More information: Xamk’s CEBIPRO page (in Finnish).