Field services for air emissions control

Regular maintenance to ensure compliance with regulations and contribute to sustainable operations

Efficient air emission control systems contribute to the overall operational efficiency of your energy plant. Regular maintenance ensures that these systems are functioning optimally, allowing the plant to effectively manage emissions while minimizing energy losses. With a well working air emission control system, the plant can mitigate their environmental impact, ensure compliance with regulations, and contribute to sustainable operations. Well-maintained systems can also extend the lifespan of the equipment and reducing the need for costly repairs or replacements.

environmental protection

regulatory compliance

worker safety

optimal plant performance

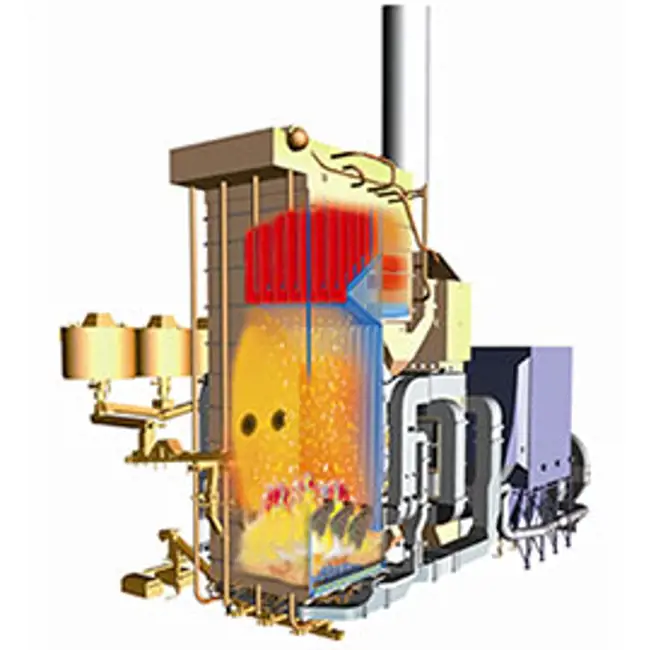

Keep NOx emissions and operation costs under control with catalyst monitoring

We can closely follows your catalyst performance. Based on a sample analysis, we can replace old catalyst blocks to ensure controlled nitrogen oxide emissions and operation costs. The catalyst samples are collected at the annual shutdown and from those samples, our experts analyze the catalyst activity and evaluate the lifetime of the catalyst. The old catalyst blocks are removed and the new blocks are installed in each layer. Valmet provides professional supervision of the work and the old catalyst blocks are disposed according to current environmental regulations.

ESP services

Utilize our power plant process expertise and modern inhouse ESP technology. We offer extensive services based on vast experience and expertise in ESP technology for power boilers and waste-to-energy boilers. We are able to offer services for any manufacturer’s ESP. Find out the full service offering for emission control.

Questions about equipment maintenance or support for equipment or process performance development?

Whether it’s a single process survey, equipment maintenance, shutdown management or full maintenance, don’t hesitate to contact your closest Valmet Service Center for guidance.

Contact usDecades long lifetime and maximized heat recovery

Valmet offers servicing for wet flue gas cleaning equipment for power boilers. Usually Valmet’s service focuses on internal parts, but also modernizations and upgrades are possible. As a manufacturer of wet flue gas cleaning systems, our service includes extensive process studies and calculations to deliver the best solutions to you. Are you to find out more about our flue gas offering?

Replace bags at the right time and secure availability

We offer bag replacement services for fabric filters for power plant applications. We have our own bag factory in Ovar, Portugal and can do an in-depth bag analysis in the factory’s laboratory. A laboratory analysis will not only give the you a good estimation of the condition of the bags, but also an estimation of when to change the current bags. In addition, our experienced teams can execute the bag replacements on site. Find out more about or bags on Fabrics for enegy.

Related articles

Download Valmet Heat, Power and Gasification Field Services Handbook

Do you need equipment maintenance or support for equipment or process performance development? This handbook gives you guidance in best practices for keeping your operation in good condition and with service interval recommendations helping you prevent unexpected failures.

Download