Washing

When additional washing effect is needed

Thickening is usually done with a disc filter. The advantages of disc filtering technology are filtrate quality and the possibility for different water fractions. The disc filter operates in a consistency range of 1-10%, with discharge consistency being optimal to pulp pressing. When additional washing effect is needed, Valmet washer can be applied to the process.

The production of secondary fiber for high quality tissue papers requires good control over the ash and fines level in the pulp. The paper machine runnability can also be improved when the recycled fibers are cleaned of sticky material, non-usable fines and ash.

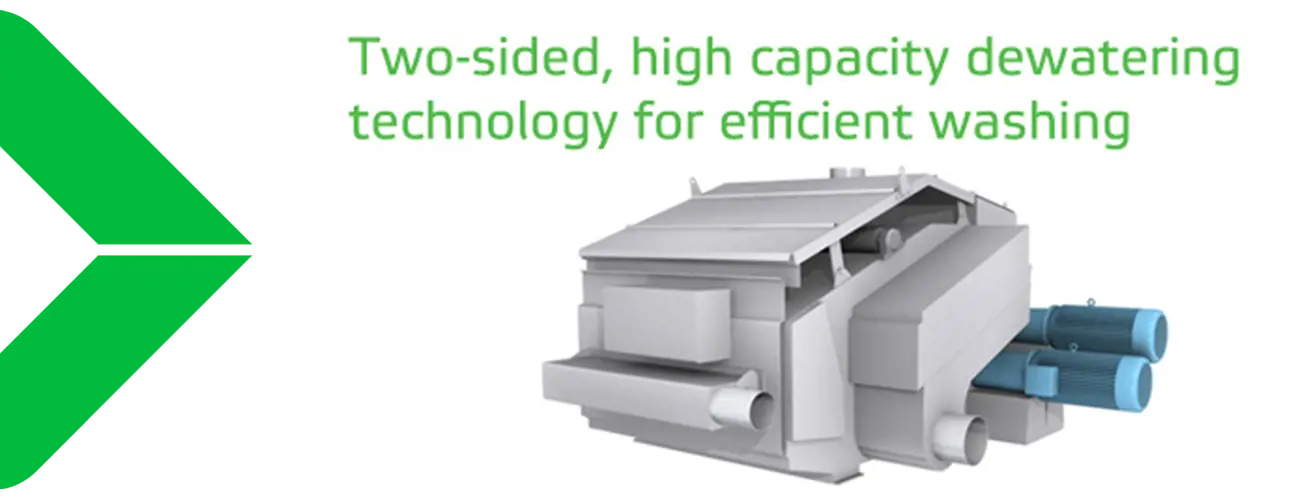

Two-sided washing

The operating principle of the two-sided washing technology is similar to the technology used in a paper machine twin-wire forming section. The compact washer design features high unit capacity and washing efficiency. The effective ash and fines removal provides many advantages compared with existing conventional washing technologies. With the gentle dewatering, reduced long fiber losses provide raw material savings and suitability for lower quality furnishes.