IntelliPress TriNip

Compact concept for lighter grades with one side web smoothness

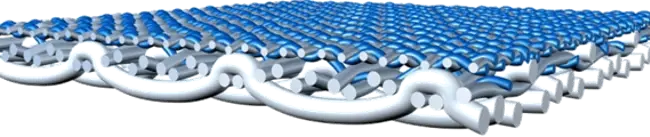

Optimal pressing conditions are essential to minimize drying energy and keep machine runnability and product quality at a high level. The Valmet IntelliPress TriNip consists of three presses combined into a compact design. The first nip is double felted and is used to control bulk. The second nip is single felted with excellent control of dewatering and provides an easy transfer to the center roll surface. The third nip is equipped with the proven IntelliNip Shoe Module, which generates a remarkable pressing impulse, combining the desired contact pressure and an optimized residence time in the nip area. Thanks to advanced pressing geometry the rewetting phenomena is highly reduced. It makes the IntelliPress TriNip the most suitable solution for low basis weight & high capacity.

High efficiency and low operation cost

High dryness and good moisture profile

Proven concept and compact design

Technology designed to wide range of applications

The IntelliPress TriNip provides high press dryness with low drying energy consumption and reduced CO2 emissions. The resulting boost in dryness greatly benefits web runnability in the open draw. This pressing arrangement is especially suited to recycled containerboard production with lighter basis weights.

The IntelliPress TriNip technology has a positive effect on the smoothness of the bottom side of the paper. The surface quality produced is sufficient for printing and creates an economical containerboard product.