Distributed Control System: Great success in competitor replacing, Indonesia

Feb 29, 2024

PT. Indah Kiat Pulp and Paper (IKPP) Perawang mill belongs to Asia Pulp & Paper (APP) Group, it is located in Sumatera island, Indonesia. Perawang mill has 9 paper machines in operation and produces approximately 1.2 million tons of paper and board per year.

PPM4, one of the paper machines in Perawang, is designed with a machine width of 2.95 meters and a speed of up to 300 mpm. The machine produces unbleached test liner recycled fluting paper. The customer was facing challenges with control system of the machine, which still used manual control in some areas, creating limited data for trouble shooting and causing unplanned downtime.

To address the challenges, customer decided to purchase Valmet DNA Distribute Control System to replace its old system, with the highlights that it has the same network connectivity as PPM9. The project was executed successfully by Valmet team in Indonesia in 2021.

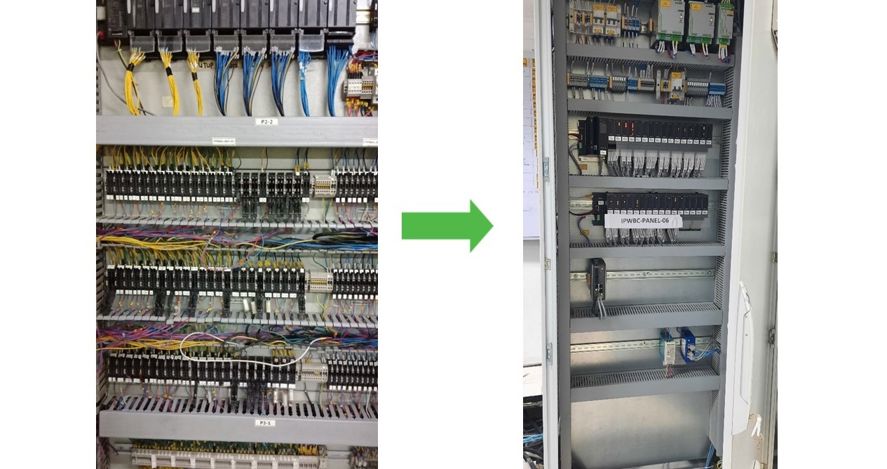

Before and after replacing a system competitor with Valmet DNA

Summary

| Location | Indah Kiat Pulp & Paper Perawang (IKPP) PPM4, Indonesia |

| Customer challenge |

|

| Solution |

|

| Results |

|

| Keywords | Asia, Automation, DCS, Distributed Control System |