Preventing chemical overdoses with Valmet WEM at Drewsen

Oct 3, 2016

Drewsen Spezialpapiere GmbH & Co. KG is a manufacturer of uncoated wood free specialty papers such as security papers, technical specialty papers, and printing and publishing papers. When faced with a challenge of high number of web breaks, Drewsen decided to install a Valmet Wet End Analyzer (Valmet WEM).

Summary

| Location | Lachendorf, Germany |

| Challenge |

High number of web breaks. Deposits and unplanned shutdowns. Chemical overdosages with both existing and new paper grades. |

| Solution |

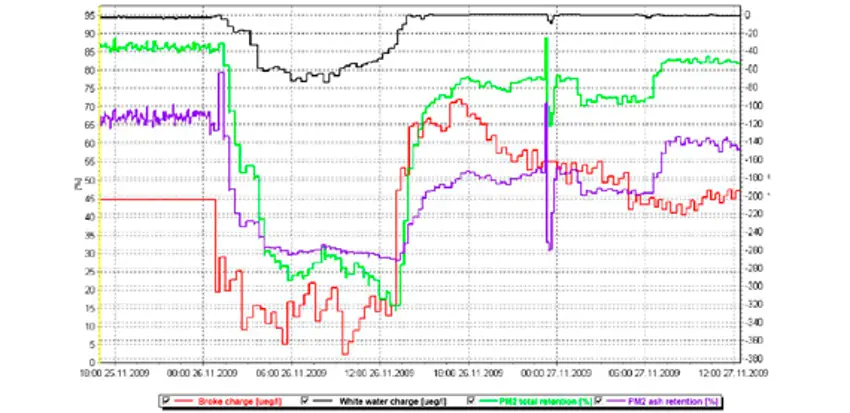

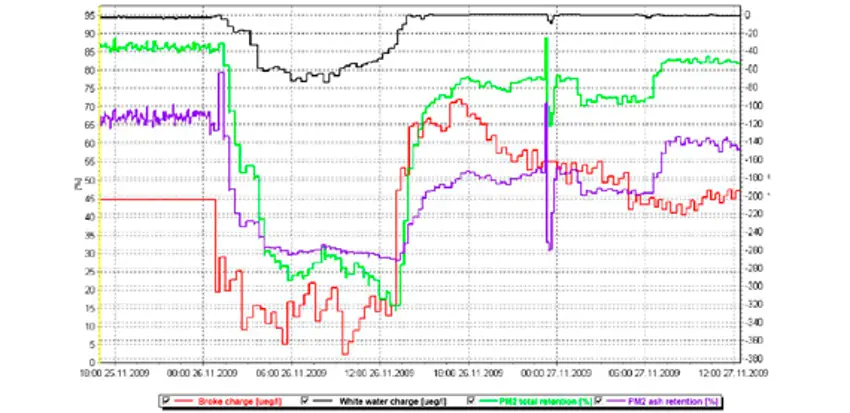

Valmet Wet End Analyzer (Valmet WEM) was installed with retention and charge module. Profound process analysis was based on WEM measurements. Online consistency and retention measurement revealed key issues in the process. Better control of clear filtrate in flotation. Retention chemical dosing based on white water consistency measurement. |

| Results |

Reduction in web breaks. The mill was able to avoid chemical overdosages. Unplanned cleaning downtime was prevented. Reduction in cost of process chemicals. Total savings are approximately €100,000. |

| Keywords | Board and paper, Automation, Europe |