LignoBoost® - the process

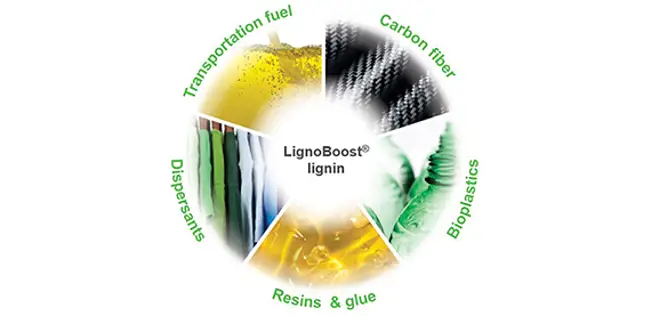

LignoBoost® is a patented lignin extraction process. Thanks to the continued development, the extracted lignin can be given properties that match the intended use. LignoBoost is fully integrated with the mill. It is designed for a safe work environment with reliable extraction of high-quality lignin.

High-quality lignin from a unique two-step process

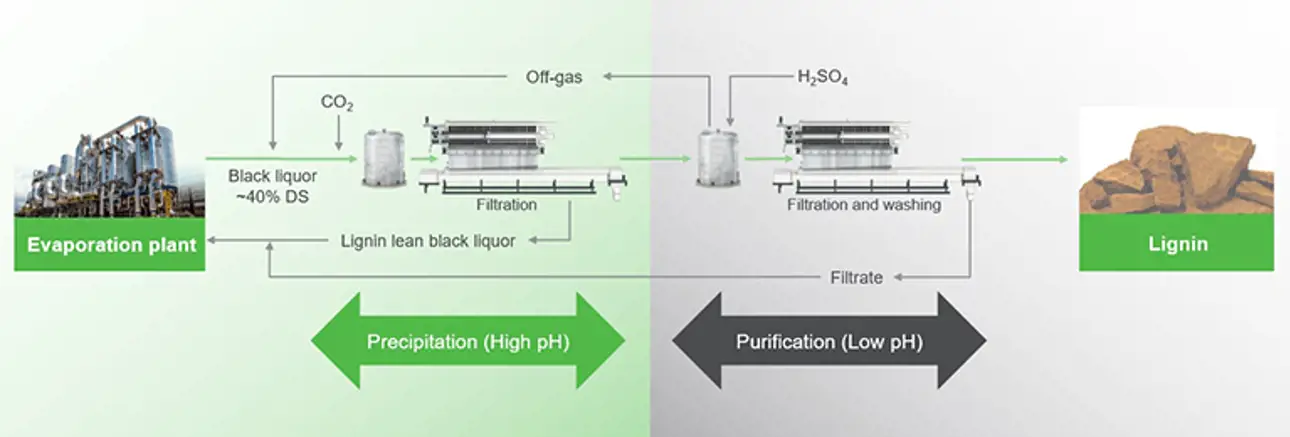

LignoBoost is a patented extraction process divided into two steps: a separation step, followed by a washing step. Dividing the extraction into two steps makes it possible to optimize the conditions in each step and produce a very high quality lignin. It also provides several options for adjusting the characteristics of the lignin. LignoBoost was initially developed by universities and research institutes, but has been commercialized and further developed by Valmet.

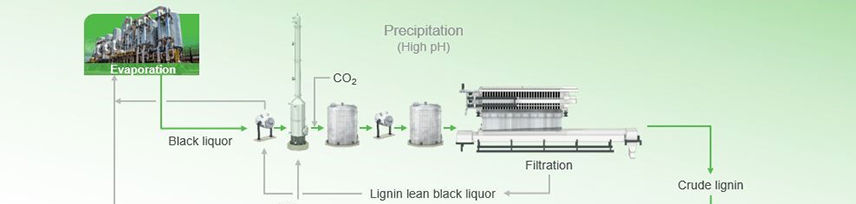

Step 1: Separation

The first step in the LignoBoost process is to separate the lignin from the mill’s black liquor. Black liquor is taken from the evaporation, and the pH is lowered with CO2 and gas from the second step of the LignoBoost process. When the pH drops, lignin precipitates and is separated from the liquor with a press filter. The output of the first step is LignoBoost crude lignin.

Step 2: Washing

In the second step, the lignin is purified. The crude lignin is washed in a low pH solution and then dewatered in a second filter press. The purity of the lignin is highly dependent on the conditions in the washing step. LignoBoost is engineered to produce a very pure lignin.

Filter presses are key

The filter presses have a major influence on the lignin extraction process and the quality of the extracted lignin. The current design of the filters and their operation is a result of Valmet’s substantial experience in lignin extraction. The filters are engineered and fully integrated with the process’s two steps. This results in very high safety and reliability.

Return flow to the mill

Lignin lean black liquor and wash water are returned to the evaporation plant. The flow of wash water is low and can normally be handled with only minor changes to the mill’s operation.

Pulp mill sulfur balance

LignoBoost uses sulfuric acid to purify the lignin. Most of the sulfur in the acid is returned to the mill with the wash water and gas from the lignin extraction process.

Valmet’s sulfuric acid plant offers a good way to control the pulp mill’s sulfur balance. Valmet has built one sulfuric acid plant and has recently been awarded the contract for a second. To learn more about Valmet’s sulfuric acid plant technology, see here.

High operational safety

Valmet’s LignoBoost technology ensures reliable and safe handling of all the flows related to lignin extraction. This includes extracted black liquor, return liquor, wash water, extraction chemicals and gas from the process. When the pH of black liquor is reduced, H2S is released, and this makes the gas handling systems an important part of a lignin extraction plant. Valmet’s in-depth knowledge of the process reactions has resulted in several advanced gas handling solutions that are integrated with the LignoBoost technology and surrounding mill. LignoBoost is built for high safety.

Safe gas handling

The gas produced in the second step of the LignoBoost process is collected and used to reduce the pH of the incoming black liquor in the first step. This solution reduces the consumption of carbon dioxide in the first step and with it, the operating cost of lignin extraction.

Excess gas from the LignoBoost process falls into the DNCG category of gases in a chemical pulp mill. This gas is collected and sent to the mill for destruction. Valmet has many solutions for safe gas handling in pulp mills.

Handling lignin in the mill

Extracted lignin needs to be stored and packaged for easy transportation to the mill’s customers. Valmet can help design solutions and supply equipment like conveyors, as well as drying and bagging systems, that ensure the simple and reliable handling of produced lignin.

Lignin as fuel in the lime kiln

Lignin is also an excellent fuel for the lime kiln. Valmet can supply modifications to the lime kiln burner and surrounding systems.

How much lignin can be removed from the black liquor?

Many pulp mills can extract up to around 25 percent of the lignin without modifying the existing mill equipment. The Stora Enso Sunila mill is designed to produce 50,000 metric tonnes of lignin per year, or 22 percent of the lignin. Lignin lean black liquor and wash water can be evaporated like a normal black liquor, and if the production of pulp is increased and the mill’s energy consumption is reduced, up to 70 percent of the lignin can be removed.

More on LignoBoost

Contact us

To discover how we can help you bring your lignin business forward, get in touch with us through the “contact us” pages or your local Valmet office. Our focus is to bring our customers' performance forward.

Contact us