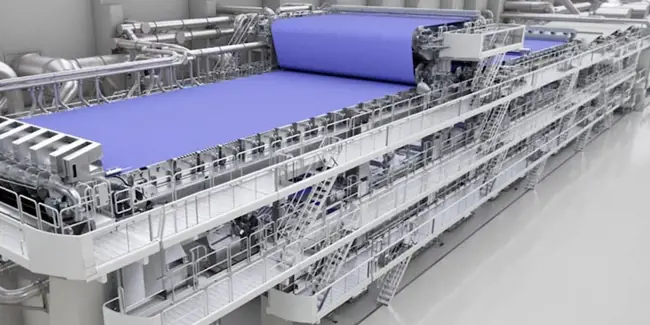

Technologies, automation and services for board and paper production

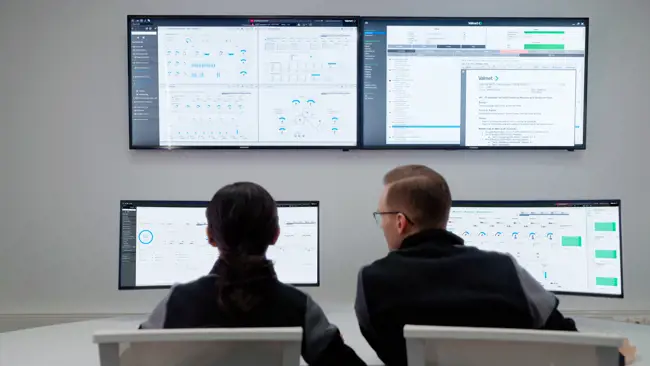

Valmet’s expertise is rooted in experience. We’ve been co-operating with our customers in more than 700 board machine and 900 paper machine deliveries worldwide. Our offering includes everything for profitable board and paper production: innovative technologies, reliability and performance adding services as well as advanced automation solutions to guarantee that your paper machine runs smoothly, energy-efficiently and uses raw materials economically.

Our solutions

New lines and rebuilds

Highlights

Explore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy