Green liquor production and place in liquor cycle (webinar)

Jan 25, 2022

Green liquor plays an important role in pulp mill operations. Poor green liquor quality can cause negative effects in critical process areas of the mill, including cooking, bleaching, chemical recovery, recausticizing and the lime kiln. Although many pulp producers face challenges related to production capacity and spatial limitations, new technology has emerged that can help mills improve green liquor quality without adding to their footprint.

In a webinar presented on Wednesday, February 2nd, Robert Carlström, John Johnson and Jeff Butler describe the part green liquor plays in the recovery process and how to optimize green liquor production.

View this free webinar HERE.

Viewers of this webinar will:

- Learn about the importance of green liquor quality and its impacts on other process areas

- Understand the fundamentals of the green liquor clarification process

- Explore results of recent CFD analysis about feed system designs

- Discover opportunities to maximize production using existing clarifiers

Here is an excerpt from the webinar...

The production of green, black and white liquors

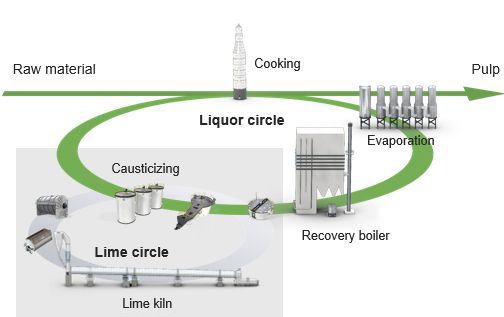

In the kraft process, the key point is recovery. There is little waste in this part of the process. Recovery is generally referred to as the recovery cycle (due to its circular nature).

The liquor and lime cycles

The sodium and calcium compounds are reused/regenerated into useful forms for the process. Lime becomes lime mud is regenerated/converted back into lime and around we go. The sodium compounds do a similar thing going through the recovery boiler. The lignin, that which is dissolved out of the wood to free the desired pulp, has fuel value. Given enough water is evaporated out of the black liquor, it can burn, generate steam and in many cases, make a mill power self-sufficient.

There are three liquors in the typical kraft mill - green, white and black. They are the sodium compounds dissolved in water making their way around their cycle in the mill. White liquor is used to cook wood chips yielding pulp and black liquor. The black liquor is a waste compound of chemicals and lignin extracted from the wood chips. It has water evaporated out of it so it can be burnt in the recovery boiler. But, when burning black liquor, the sodium compounds are inorganic, don’t burn and accumulate in the bottom of the boiler as molten smelt. That smelt flows out of the boiler into the smelt dissolving tank where it is blended with weak wash and possible water to make green liquor. Green liquor is clarified, suspended solids removed, and then mixed with lime to make white liquor and lime mud. The mud is removed, the white liquor goes to the digester as the cooking chemical ... and around the cycle we go.

Green liquor can have a green tint to it. Black liquor is black and white liquor can be from clear to amber depending on strength and suspended solids content.

For more information on improving the production and usage of liquor in the recovery cycle, watch the webinar and contact your Valmet representative.