Press section case study - Inspection of premature felt failures

Aug 16, 2022

A Canadian mill was having premature felt failures and felt this was due to controlled crown (CC) roll failures. They asked Valmet to perform an inspection of the 3rd press felt run and see if this was indeed the case.

Valmet personnel arrived onsite and inspected the machine while running. Past and current problems with the 3rd press were discussed. During the shutdown the next day, Valmet assisted the mill in making corrective adjustments to the guide roll, the 3rd press CC roll, granite roll and felt stretcher assembly. While performing the E-nip in the 3rd press, a caustic wash valve was accidentally bumped in an open position. (This valve was located on the floor in the path of a CD walk area, and had to be stepped over to continue crossing through the machine.)

Specific findings

The guide roll was found to have too little travel, with stiff springs, and was being run in the extreme top position. Changing the springs helped, but only somewhat. Machine of the frames was warranted.

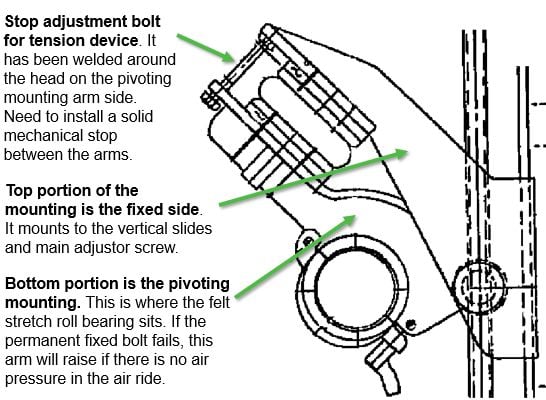

The TS seam straightener device was found to wear quickly, possibly from over-tensioning the press felt. The DS unit had been modified so that it was no longer a functioning tool. The adjusting bolt had been replaced by a permanent bolt. If air pressure was lost in the air ride (or the air ride was no longer used) premature felt failure would occur. A permanent mechanical stop between the two mountings was needed (see figure).

Installation of mechanical stop between mountings

The granite roll was checked while loaded to the CC roll. The TS and DS were out of spec and needed correction to allow even loading pressure tend side to drive side

The CC roll had been replaced a few weeks prior to this inspection because of a cover failure. The CC roll / granite roll alignment should be checked annually for level and square to each other, as alignment tolerance should not exceed 0.003" per 100" in machine width for both rolls.

The felt run rolls checked out OK - good roll covers and sound bearings.

Recommendations made

Valmet made the following recommendations to the mill in a formal report, and discussed the need for and value of each:

- Change the location of the caustic valve, and add it to the lockout/tagout program, only to be unlocked while operations is cleaning the press felts.

- Machine the mechanical stops in the guide frames to allow the full travel as designed. This could be done onsite by the mill during a normal felt change on the press.

- Purchase the correct design tension springs for the current roll weight used in the guide position.

- Set the 3rd press loading air rides to the correct dimension. These need to be identical in dimension and should be set at 10.0" when fully loaded.

- The basement stretch roll assembly had had repeatable component failures. The mill should verify if the stretch assembly is over-tensioned, adding more than design load on the designed components.

- Verify the current press crown curves for the current operating loads, speeds and paper being produced. Valmet would verify using information sent from the mill.

- Conduct an annual alignment check of the CC roll / granite roll, until cover failures are eliminated.

- Consider a paper moisture CD profile study within the press section. This would isolate problem areas.

- Consider a condition test, audit and thorough inspection of the CC roll hydraulic unit.

- Consider replacing the palm guide valve with the new Valmet version.

Press Section Process & Condition Test

Press section service packages consist of testing, inspections and overhaul procedures. Testing and inspections help determine the mechanical condition of components, the operation of machine automation and the scope of overhaul needs. Testing is carried out during both production and special maintenance shutdowns. The shutdown time required for testing is usually 8-12 hours, whereas the time needed for maintenance work depends on the item serviced and the amount of work required.

Is your press section failing, causing machine clothing failures or otherwise not performing up to snuff? Contact your Valmet representative and get an expert onsite to troubleshoot your machine line.