Long-term collaboration pays off in many ways

Jul 4, 2023

There have been many fruits of the collaboration of Saica Paper and Valmet over the past seventeen years. Today, Saica Paper takes pride in its world-class maintenance operations in Spain.

Established in 1943, Saica Paper is committed to providing sustainable paper solutions for corrugated cardboard and packaging, and to developing circularity in waste management in Europe and the USA. In Spain, Saica runs two containerboard mills: the Zaragoza city mill and the El Burgo de Ebro mill. Their combined production amounts to 1.8 million tonnes of corrugated cardboard per year, with five paper machines.

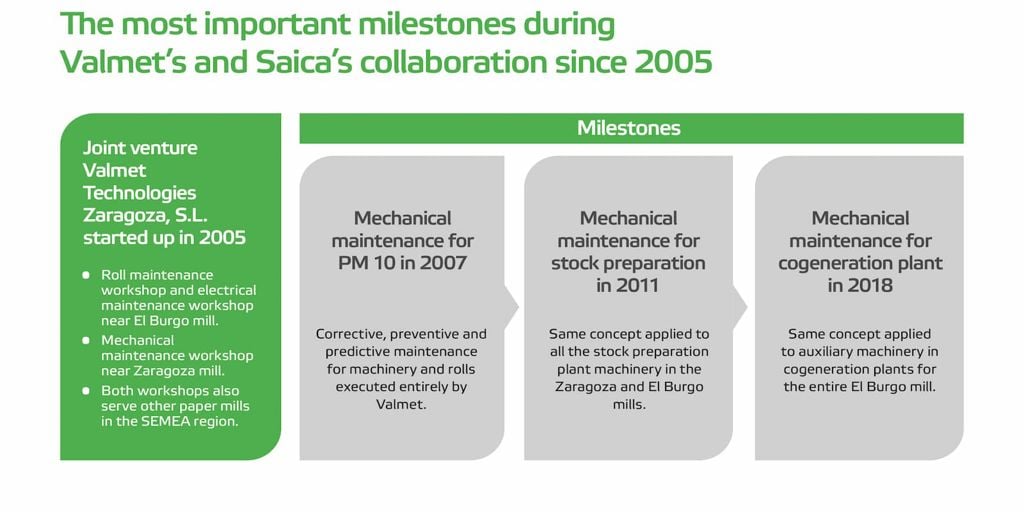

The collaboration with Valmet started in 2005 with the establishment of a joint venture, Valmet Technologies Zaragoza S.L, to provide mechanical and roll maintenance services close to the Zaragoza mill. “This signaled the beginning of a confidence that has led to seventeen years of successful collaboration,” Saica Paper’s Industrial Director, Fernando Carroquino, explains. In addition to Saica, the joint venture serves other mills in the Iberian Peninsula.

A strong partner for better performance

The beginning of the long-term collaboration with Valmet was marked by a change of vision for the maintenance services at Saica. “We decided to change our maintenance focus from repairing and fixing and considering maintenance an inevitable cost to reducing downtime and actually improving our papermaking operations,” Maintenance Manager David Plou of Saica Paper, says. This vision called for a strong partner like Valmet.

Valmet was expected to add value to the mills’ maintenance operations through its in-depth paper machinery knowledge and skills, as well as through state-of-the art diagnostic procedures and service methods.

“We needed Valmet to find new solutions that would help us reduce our maintenance costs and improve the performance of our papermaking equipment,” says David Plou, Maintenance Manager, Saica Paper.

Evolving for the best maintenance strategies

At first, Saica aimed for a flexible dual maintenance model in which prioritization and expertise were to be kept in-house, and Valmet was involved in areas where its value was considered greatest. This model has evolved over the years, with Valmet entrusted with larger responsibilities for specific equipment and plants.

“Continuous improvement is almost in our company DNA. With Valmet, we’ve designed the best maintenance strategies for our equipment,” Plou underlines. “Valmet took over the corrective, preventive and predictive maintenance for the machinery and roll repair of PM 10. Its shutdown intervals have been progressively extended over the years. Some concepts have subsequently been copy-pasted to other plants and equipment.”

Support based on agreement

Valmet is aware of Saica’s investment plans and has been a helping hand in putting them into practice. For example, Valmet has been involved in the waste-to-energy plant, off-line coating machine and paper machine winder investments.

“When we lack the experience, as in the case of the coating machines, Valmet offers the expert knowledge,” Carroquino explains. “We also like developing things like the bale tester together,” he continues. “The magic bale tester has been amazing, because once you have it there, the quality of bales improves immediately – even if the device isn’t connected yet,” Carroquino smiles.

“Support for investment is one thing, but the support from agreements for the mill and roll maintenance, including spare parts and fabrics, is even more important for us. Based on these agreements, Valmet’s expertise is available at all levels of our organization, and they can easily be contacted for help if there’s a problem.”

It’s all about trust!

For Saica, the foundation of successful collaboration and partnership is trust.

“Trust, trust, and trust. We continue working together because we both know that the other half is there whenever they’re needed,” Fernando Carroquino, Industrial Director, Saica Paper, states firmly.

“We can rely on Valmet meeting the targets and being fully aligned with our objectives. For example, with safety as our key driver, we have developed a preventive culture, and Valmet has provided safety training for its teams,” Plou adds. “And Valmet’s flexibility to adapt to our requirements has been the key to correct actions over the years.”

World-class maintenance operations

The years of collaboration with Valmet have paid off in many ways, which is also seen in the company KPIs. They have continually indicated less time lost in unplanned maintenance or safety incidents.

We have well-established shared routines, and all five of our paper machines have reached more than 92 percent efficiency, with hardly any time lost to unplanned shutdowns. Such results translate to more tonnes per year,” Plou underlines.

“As a result, we can consider ourselves to have world-class maintenance operations,” he concludes.

Sustainability development

Saica is known for its sustainability goals and its wide range of 100-percent recycled corrugated cardboard products. “We recycle everything, and that is our idea of sustainability,” says Carroquino. “We also need to produce paper sustainably, and we need to reduce water, energy and fiber consumption,” he points out.

An example of how they are reaching for these goals is a sustainability workshop conducted with Valmet to highlight opportunities to reduce energy consumption by optimizing equipment or operations. “This event gathered our top management and Valmet’s best people for an open-minded discussion and to develop new ideas, solutions and technologies,” says Carroquino.

Valmet contact person

Name: Eduardo Ruiz Urrutia

Title: Vice President SEMEA Sales, Valmet

Tel: +34 60 7939511

Email: Eduardo.Ruiz@valmet.com

Text: Sari Lehtonen-Lammi, Photos: Thomas Evaldsen

For Saica, the foundation of successful collaboration and partnership is trust."