A cost-effective upgrade to the headbox at Cheng Loong Corporation Ta Yuan Mill with Valmet RetroDilution

Sep 25, 2023

Ta Yan Mill Board mill is in Taoyuan City, Taiwan, and is equipped with a two-ply fourdrinier wire. In 2022, after numerous exchanges and comparisons, CLC Paper decided to collaborate with Valmet to achieve improved paper quality through a RetroDilution upgrade to PM2 headbox, to meet market demand.

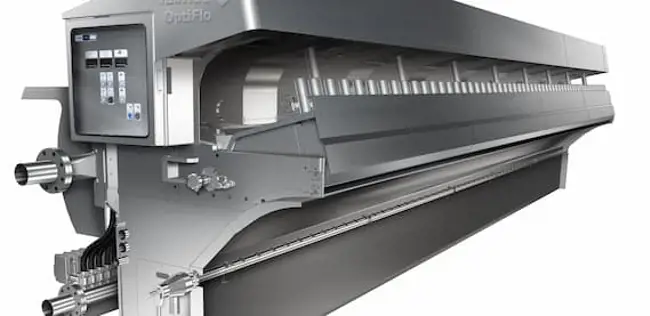

The RetroDilution for headbox upgrade is a dilution control retrofit that provides a cost-effective way to modernize existing slice-lip-controlled headboxes into dilution-controlled ones. The control principle involves receiving automatic software banner scanning data, providing feedback to the control system, and adjusting the bone-dry basis weight (BW) through a single adjustment point of consistency on the wire, to achieve uniformity in the CD profile.

Browen Li, Product Manager at Valmet, explains, "Valmet's unique dilution water ring injection makes dilution control of the CD profile more significant and enables better paper stability without affecting fiber distribution. It shortens the time required to stabilize the paper after shutdown or extended breaks, as well as during paper grade changes, resulting in fewer breaks and improved runnability.

After the headbox RetroDilution upgrade, PM2 was successfully restarted on April 17, 2023. Following the restart, the 2-sigma value of 180g bone-dry basis weight was reduced from the previous 1.82 to 0.8, representing an improvement of more than 50%. The customer was highly satisfied with the upgrade.

Many years ago, Valmet successfully completed the upgrade for BM1, and the PM2 RetroDilution upgrade has also been very successful. The significant improvement in CD bone-dry basis weight has played a crucial role in paper machine operation, reducing raw material and energy consumption, and boosting market sales. Valmet remains as trustworthy as ever," says Qingshan Chen, Production Director of CLC, Cheng Loong Corporation, Taoyua.

Technical information:

| Customer | Taiwan Cheng Loong Corporation, PM2 |

| Grade | Testliner or Fluting |

| Capacity | 250,000 t/a |

| Slice width | 5040mm |

| Wire width | 5240 mm |

| Width on reel | 4600 mm |

| Basic weight | 100-200g/m2 |

| Design speed | 850m/min |

| Start up | 1988 |