The BioCMPC project – A leap in sustainability and operational efficiency

Aug 9, 2023

BioCMPC – a major upgrade and modernization project of CMPC Guaíba mill’s line 2 – opens the next chapter in the mill’s story. The investment will result in a major leap in the mill’ sustainability and operational efficiency, and increase their annual pulp production capacity by 350 thousand tonnes.

CMPC acquired the Guaíba mill, located in southern Brazil in the Rio Grande do Sul state, in December 2009. The first line was originally built in 1972, and a second production line, Guaíba 2, started up in 2015. In 2021, CMPC decided to significantly invest in modernizing their operations and in new environmental control and management measures, with Valmet as the key technology and automation partner.

We’ve reached production records at the mill in the last few years, even with the upgrade project ongoing.

Mauricio Harger, General Director of CMPC in Brazil, explains the project’s background, “The BioCMPC project unites sustainability and operational efficiency, establishing an industrial operation that’s more aligned with society’s values and is one of the world’s most sustainable plants. The project is strongly rooted in our 2030 strategy, which covers sustainability, talent development, competitiveness, customer focus, and growth and innovation.”

Supporting local communities

CMPC aims to be a leader in sustainability and a global change agent in social development.

“CMPC operates 48 mills and plants in eight Latin American countries. Our mills support local communities and growth. We have calculated that for every direct CMPC employee, there are seven other employees in the whole chain, from plantations to logistics,” Harger says.

“The Guaíba mill is inside the city, with neighbors living just across the street. This gives us a lot of additional requirements, and the operations need to be impeccable. If we have any deviations, we receive calls from our neighbors within three minutes. This has also impacted our project implementation strategy. For example, we aim to do the work between 8 a.m. and 6 p.m., and we’ve built additional acoustic banners,” he says.

"Safety is always one of our main focus areas,” says Fabrizio Contin, Valmet’s Project Director for the BioCMPC project.

An investment focused on sustainability

“The BioCMPC project is a major upgrade and modernization of the Guaíba 2 production line. With a total investment of BRL 2.75 billion (about USD 540 million) and 31 improvement actions, it will result in an increase in annual production capacity of 350 thousand tonnes. Our main challenges are that we don’t have much additional space, and that we’re running the mill at the same time as we’re doing the upgrades. I’m very proud that even with the upgrade project ongoing, we’ve been able to reach production records at the mill in the last few years,” Harger explains.

We are now upgrading the process and production to the next level.

“We’re also setting up an environmental control center. This is a 24/7 control room that focuses only on environmental KPIs and parameters, and we’ll be able to predict any deviations in environmental parameters that could impact the community, like odor, noise or particulate material,” Harger adds.

Upgrades for almost all process islands

Sami Riekkola, Valmet’s Pulp and Energy Business Line President, adds, “Valmet is the main partner in the project, and we’re delivering most of the new technology and automation. This includes a new recovery boiler and upgrades to almost all process islands. The new high-power recovery boiler with electrostatic precipitators (ESPs) will enable additional steam and power production with minimal particulate emissions. The fiberline upgrade includes our first ever delivery of TwinRoll 2288 wash presses, which will secure low chemical consumption.”

Valmet’s Pulp and Energy Project Director, Pekka Rikkinen, says, “Executing such an extensive upgrade in an operating mill is even more complex than a greenfield project. It covers all areas of pulp production, mechanically integrating new equipment with existing equipment, as well as significantly modifying the control system to upgrade the process and production to the next level.”

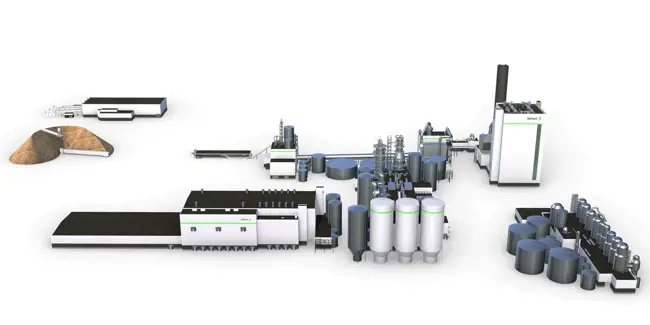

CMPC Guaíba line 2 was started up in 2015. Valmet delivers the key technology and automation for the major upgrade including a new recovery boiler and a new effect for the evaporation plant.

“With the new recovery boiler, we can decommission our old coal-fired boiler,” says Harger. “We will have a small natural gas package boiler, but only for use in start-ups, shutdowns and disturbance situations. This will significantly reduce our CO2 emissions and enable additional renewable electricity production. We’re also further improving our already state-of-the-art odorous gas collection and handling. In addition, we will reduce our water consumption and particulate emissions and noise levels around the mill.”

Project approaching the final stretch

The project has continued, even when faced with external global challenges – the Covid-19 pandemic, the war in Ukraine and inflation – which created unforeseen logistical and material availability issues.

“It has demanded extra effort from everyone involved,” Rikkinen says. “We’ve especially focused on communication, scheduling and follow-up – and corrective actions are taken immediately if there are any deviations. We’ve enjoyed excellent cooperation between all Valmet parties, as well as with the customer. CMPC representatives have visited Sweden and Finland to monitor our main European technology and automation deliveries. Special attention has been paid to APCs (Advanced Process Controls) and simulator deliveries to get the best value from the mill’s future operation.”

The fiberline upgrade includes Valmet's first ever delivery of TwinRoll 2288 wash presses, which will secure low chemical consumption.

“In a project like this, it is very important that the people working in different teams get to know each other,” adds Fabrizio Contin, Valmet’s Project Director for the BioCMPC project. “It makes cooperation much smoother, and it’s easier to solve any challenges. Safety is always one of our main focus areas. When we execute a project in an operating mill with very limited work areas, safe working practices are even more important. We can say that we’ve had a good result in terms of safety, schedule and quality so far.”

A major part of the work on site was done during shutdowns in May 2022 and 2023. The final parts will be undertaken during the October 2023 shutdown and will include the interconnection of the upgraded areas to the existing areas.

In the pulp drying line several upgrades were done to get higher screening capacity, improve dewatering, boost evaporation capacity, recover heat in an efficient way and handle the increased capacity on the existing and new baling lines.

“We’re working on detailing and planning all the work for this shutdown and analyzing all the critical paths, as well as preparing contingency plans for each of them,” Contin says.

“I’m very enthusiastic about the project’s finalization phase and look forward to a successful ramp-up from November 2023 onward to make the Guaíba mill one of the most sustainable in Brazil,” Harger concludes.

Text Lotta Forssell PHOTOS Fabiano Panizzi

The scope of Valmet's delivery

Valmet’s delivery includes a new high-power recovery boiler with electrostatic precipitators. The cooking and fiberline, causticizing, lime kiln and pulp drying are also being upgraded. An additional baling line is being added, as well as an additional evaporation effect and expanded ash leaching. The upgraded automation system will include flow control solutions, advanced new process controls and an operator training simulator.

Related articles