When small things make a big difference

Oct 27, 2023

UIPSA’s Winder Reliability Agreement with Valmet has been effective for two decades – and that is continuing. Over the years, the cooperation has led to numerous small improvements, resulting in significant development in the winder’s capacity, reliability and safety.

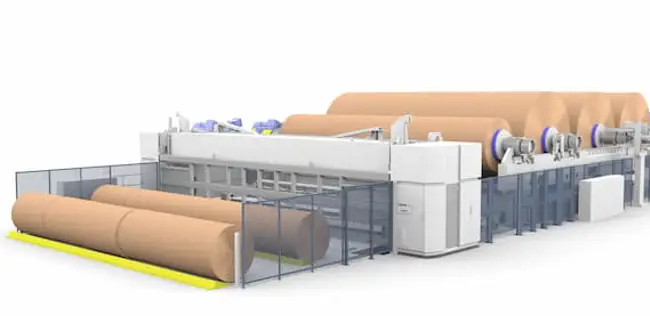

UIPSA, Union Industrial Papelera S.A, began the production of 100 percent recycled testliner and fluting at its mill in La Pobla de Claramunt, Spain, in 1975. At the turn of the century, the mill’s PM 1 underwent a major rebuild, and a new Valmet winder was also installed.

UIPSA considers the winder to be as important as the board machine itself. They find the winder’s trouble-free operation and capacity essential for the entire mill’s performance. After cooperating closely with Valmet during their new winder’s delivery and start-up phase, UIPSA wanted to secure its optimal performance for the years to come and decided to sign a Winder Reliability Agreement in 2003.

“We believe that as the original equipment manufacturer Valmet was and remains the number one choice for us for such a long-term partnership. Thanks to Valmet’s support, we’ve been able to plan and execute our daily maintenance routines, implement numerous small improvements, optimize the winding process and operating practices and develop the winder’s safety in many ways over the years,” Juan Carlos Irastorza, Mill Manager at UIPSA, says.

Striving for continuous improvement

Valmet’s agreements are always tailored to meet the customer’s needs. Valmet has delivered numerous rebuilds, spare parts and maintenance, training, and services for maintenance and shutdown planning for UIPSA – including short- and long-term actions that maintain and improve the condition and performance of the winder and maintain its compatibility with the board machine’s requirements.

“The most important thing is the continuous improvement for which we strive year after year. The upgrades we’ve invested in might seem minor, but they’ve ultimately had a major effect on the winder’s overall performance. I appreciate Valmet’s readiness and ability to support us along the way and to help us solve our problems and find answers to our questions – it’s the key to our success,” Irastorza says.

Jaume Creixell, Maintenance Manager, highlights the importance of maintenance for the winder’s overall performance.

“There’s a lot we can do with small improvements to maintain the winder’s outstanding performance. However, it’s the day-to-day maintenance that helps us keep the problems close to zero. Valmet’s support in maintenance planning has been of the utmost importance,” he says.

Confidence is built through performance

The winder’s performance has been followed up by several key performance indicators throughout the agreement period. Incredibly, the statistics show that the average unplanned annual downtime for the winder has been less than three hours in the past twenty years.

“We’re very happy with the development we’ve seen over the years, as well as with our winder’s current condition. In my opinion, success is about the confidence we have in Valmet’s commitment to our mill and targets, and especially the confidence in the team that supports us. I appreciate the trust and the two-way communication we have between the teams – it’s important that we discuss any challenges and future plans we might have openly yet confidentially,” Irastorza says.

Toward a more sustainable future

As the next step in the continuous journey of improvement, UIPSA is exploring various options to further increase the winder’s capacity to meet the plans they have for future board production.

“In addition, today more than ever, we want to be more respectful of the environment. We’ve already taken real steps in improving water, chemical and energy efficiency with various measures, but I believe there’s a lot more we can do together for sustainability,” Irastorza concludes.

Pictured from left: Jaume Creixell, Maintenance Manager, Kai Odé, Senior Sales Manager, Juan Carlos Irastorza, Mill Manager, Albert Irastorza, Production, Mika Savolainen, Manager, Field Services and Francesc Sedo, Finishing Engineer.

For further information:

Kai Odé, Senior Sales Manager, EMEA, BTS Agreements and Field Services, tel. +358 50 317 3736, kai.ode@valmet.com

Mika Savolainen, Manager, Field Services, EMEA, tel. +358 50 317 0690, mika.k.savolainen@valmet.com

Related content