Energy savings through optimized doctoring at the dryer section

Apr 22, 2024

How to save energy in papermaking with doctoring?

Did you know you can reduce the energy consumption of your board or paper machine while also gaining additional benefits such as improved drying capacity, better runnability, lower doctoring costs and less waste? All this without major capital outlays, long payback times or extended shutdowns. Yes, you can! With Valmet’s doctoring products and optimized doctoring processes, the energy consumption of any production line can be reduced without compromising its performance

Almost all rolls and cylinders need doctoring. The primary functions of doctors are simple: they shed the sheet at sheet breaks or sheet threading and remove excess water and contaminants from the doctored roll surface. The keys to an optimal doctoring process lie in state-of-the-art blade materials, modern roll covers and optimal doctoring parameters.

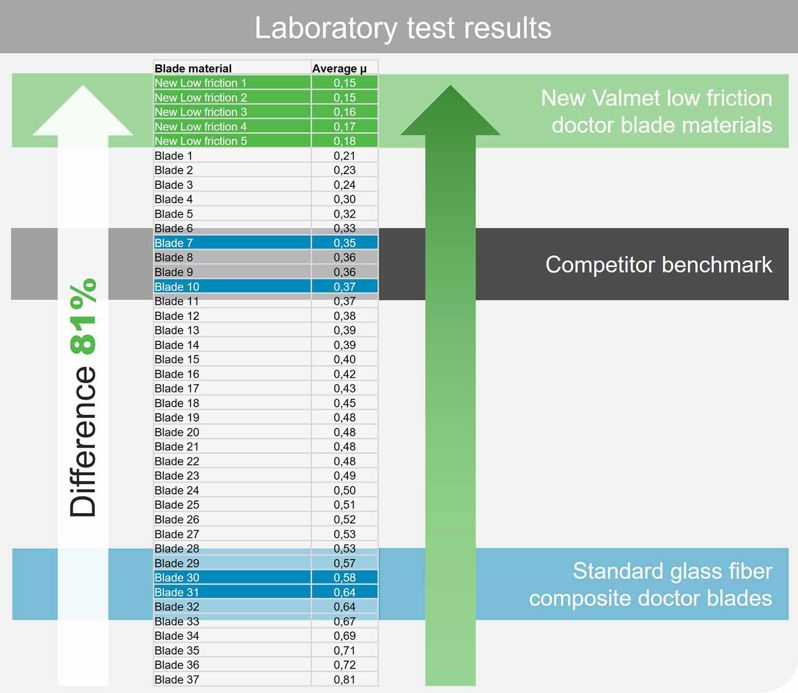

Over the years, Valmet has developed many innovations related to material technology of roll covers and doctor blades, more and more targeting to solutions that save energy, chemicals and raw materials. Just recently, Valmet introduced the new sustainable low-friction doctor blades that help to further improve the energy efficiency at the dryer section of board and paper machines.

A huge energy-saving potential at the drying section

The total number of doctoring positions varies between production lines: modern board and paper machines typically employ 50 to 120 doctors. Pressing a doctor blade against a roll surface generates friction also known as braking effect. In other words, there are 50 to 120 mechanical brakes (doctor blades) on a machine line, attempting to slow down the speed generated by electric motors. Approximately 50 to 90% of these mechanical brakes are located at the dryer section.

The dryer section, in turn, affects machine speed, the sheet’s moisture profile and break frequency, as well as overall energy balance and power consumption. Its good runnability relies on trouble-free doctoring and clean cylinders. Due to the number of dryer cylinders involved, even small friction reductions between doctor blades and cylinders are multiplied severalfold along the section, thereby producing considerable savings.

The acting coefficient of friction, which cannot be determined through theoretical calculations but must be measured empirically, depends on several factors. High friction can be a real issue at the dryer section, especially since there are several hot drying cylinders that are doctored without any lubrication. Dryer section start-up problems are often caused by the fact that the coefficient of static friction is higher than the coefficient of kinetic friction for a given material. Under such conditions, it is not uncommon to overload the motor, gearbox or other power transmission components. Additionally, the hot and humid surroundings of the dryer section constantly challenge doctor blade materials.

Conventional doctor blade materials, like bronze, steel and fiberglass, have relatively high coefficients of friction, resulting in high energy consumption rates. Despite this, they are still widely used due to their relatively lower price and deep-rooted mill practice. In other words, the dryer section represents a good potential source of energy cost savings at many mills.

Valmet continuously strives to develop new and innovative blade materials, conducts friction tests and analyzes the results to find the optimal combination of blade material and other doctoring parameters. For instance, blade performance can be measured against doctored surface, doctor loading pressure, blade angle, blade thickness and machine speed.

Simple doctoring improvement process for reduced energy costs

Even when theory and calculations clearly point to potential energy savings, results are often verified in practice through comprehensive trials to determine the real savings potential of a specific machine.

For years, Valmet has used a simple step-by-step improvement process that enables papermakers to reduce their doctoring-related dryer section energy consumption. The process starts with a thorough study of the current status of doctoring which produces a clear project plan and recommendations for optimal doctoring parameters and blade materials. The mechanical condition of all doctoring components is checked, and a list of required maintenance work and replacement parts is generated. All maintenance work and spare parts can also be included in the agreed project scope.

Today, Valmet’s doctoring offering includes a complete portfolio of doctor blades, holders and accessories. The flagship products of the offering are the new low-friction doctor blades already mentioned above. These carbon and glass reinforced composite blades with low friction fillers have energy-saving features never seen before. Choosing the new doctor blades leads to less CO2 emissions and reduced operation costs. Additionally, the blades contribute to cleaner dryer cylinders, and thanks to increased blade lifetime, result in less doctor blade usage.

Excellent results through optimized doctoring

In a recent real-life trial, the customer’s original blades and doctoring parameters were compared to Valmet’s new low-friction blades. First, they were tested with the original parameters, and later, with optimized doctoring parameters. Based on the data provided by the customer, the absolute electric consumption decreased by over 26% when comparing the original blades and parameters to Valmet’s low-friction blades with optimized doctoring parameters. This reduction led to remarkable savings in energy costs and reduced CO2 emissions.

In addition to reduced energy consumption, the state-of-the-art doctoring products and improved doctoring processes help the mill improve cylinder drying capacity and runnability. They also contribute to achieving better paper quality, higher production efficiency and cost savings in both doctoring and operating costs – with a clear positive impact also on the safety and sustainability of the mill’s operations.