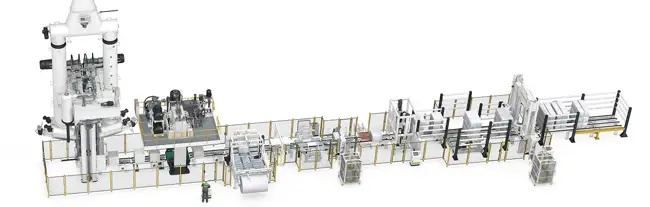

Pulp drying and baling

Move forward with world record technology

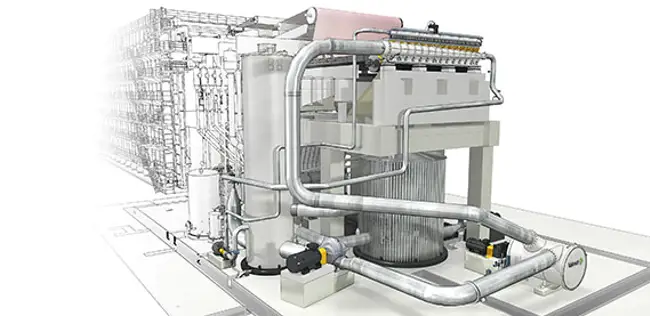

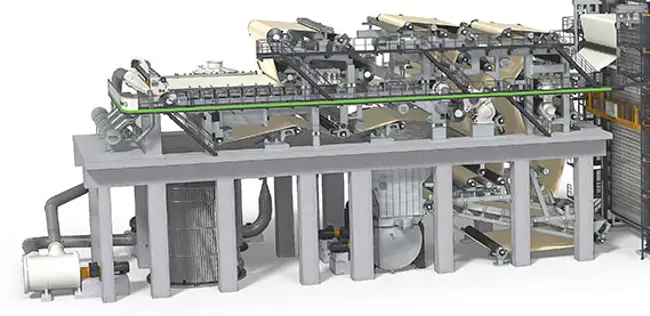

Valmet offers best available technology for efficient and economic pulp drying and baling. Our wide and flexible technology offering facilitates several pulp grades with end products like dissolving, fluff and market pulp. With efficient solutions we offer you the lowest steam and energy consumption on the market. The high availability and high speed of our reliable equipment means more production.

Leader in speciality pulp grades, roll finishing and dissolving

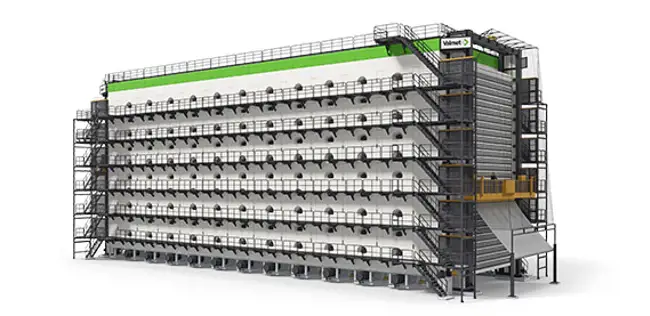

Supplier of the biggest machines in the world

Capacities from 500 to 4300 t/d

Lowest steam and energy consumption

Steam consumption: 800 kg/Adt

Energy consumption: 100 kW/Adt

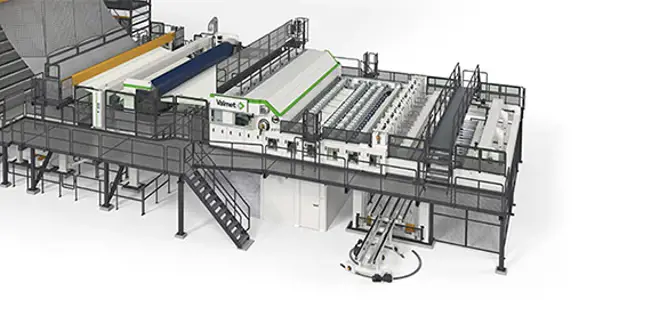

Highest cutter availability and high speed baling line

High speed: 300 bales/h

Our professionals have built the largest pulp dryers in the world and applied them successfully in three different continents. Valmet drying machines hold world record capacities with gap former and fourdrinier technologies, with single machines daily productions topping over 4300 tons.

An easy-to-run and high capacity technology concept gives flexibility to operate different wood species and an advantageous overall economy.

Improve your performance together with Valmet.

Optimized and stable operation with advanced bale weight control

By utilizing the data collected from the scale by the Bale press, optimized operation can be achieved. The data is fed back in the process, adjusting settings to improve performance, step by step all the way back to the headbox. With this, all bales are kept with the same width, even during recirculation of grades change. The data is also used to adjust the profile to keep all bales with the same weight, compensating moisture differences caused by felts or other process variations.

Pulp drying automation in CMPC Guaiba II, Brazil, is a part of Valmet's mill-wide system.

Continous success by close collaboration and the right combination of services for every stage of the lifecycle

To maintain the competitiveness of your baling processes and to develop them throughout the lifecycle. We provide a wide range of solutions for upgrade and improve your existing baling equipment, processes and machinery. The scope is always based on your specific needs and the solutions are tailored to maximize the performance of your specific installation.

Our services team support and guide you in finding cost effcient solutions to get the most out of your baling processes and equipment. We offer various forms of services and advanced diagnostics through Valmet Baling Quality System to ensure that you always maintain high availability and capacity of your baling line.

A Service Agreement offers close collaboration to reach agreed targets, the scope is always tailored to your needs to ensure reliability, quality and increased machine equipment, electrical components and automation systems lifetime.

Our expertise is at your service

We at Valmet are committed to moving our customers performance forward and ensure smooth, disruption-free operation, supporting you all the way.

Contact us