Working safety and usability

Safe working conditions for all paper mill employees

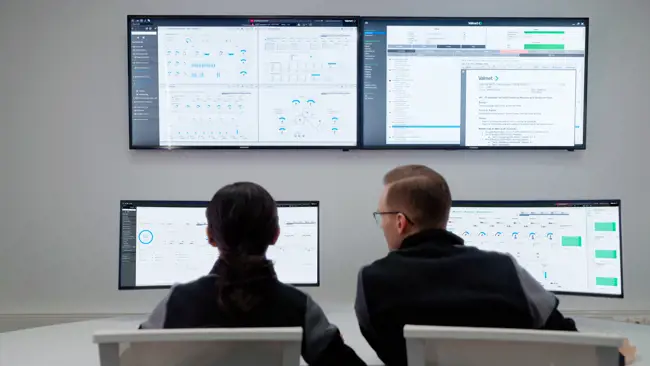

Valmet's working environment improvements aim to ensure safe working conditions for all paper mill employees. A healthy and pleasant workplace is not only important for the well-being of employees, but it also improves their motivation and commitment, and consequently their productivity. All our products are engineered to meet applicable national and local safety standards.

Cleaner air, less noise and safe operations

Safety and usability play an important role in Valmet’s innovative paper and board manufacturing line engineering. Our working environment improvements consist of such items as dust and humidity control and sound attenuation solutions for cleaner and healthier machine hall air. The user-friendly engineering and innovative solutions further improve operator safety and thereby help to make machine maintenance and cleaning easier and more efficient.

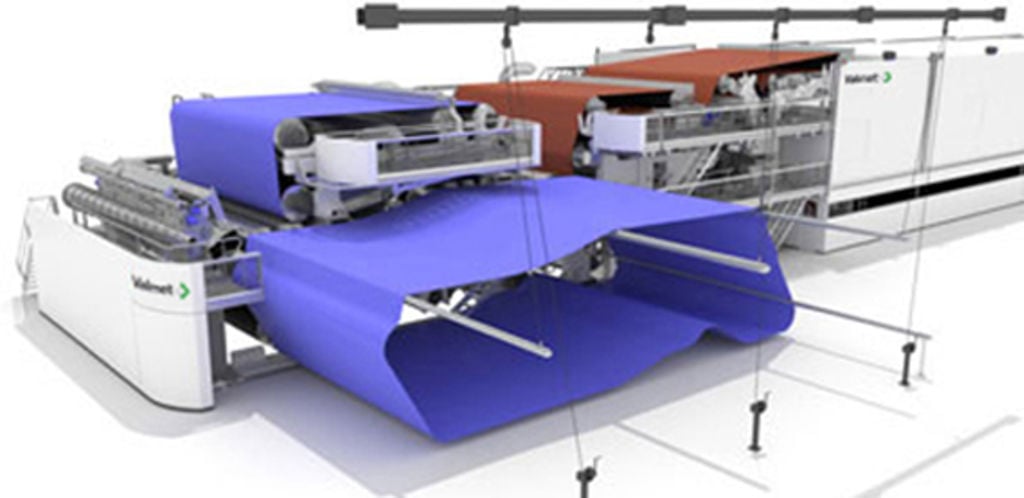

One excellent example of working environment improvements is the design of our new modular OptiConcept M paper and board machine, which emphasizes usability, safety, and a good working environment. These are achieved through such features as new walkway configurations, access ways through the machine, integrated automation towers, handy mobile equipment, and an innovative fabric insertion unit.

Fabric insertion units simplify the fabric changing process by carrying the weight of frames and rolls on the tending side, without cantilevering.

Read about safety and paper machine design

Want to talk to our board & paper experts?

If you wish to get further information like technical specifications or details, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsExplore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy