Introducing the Valmet black pellet plant — A new, sustainable income stream for power plants

Nov 3, 2015

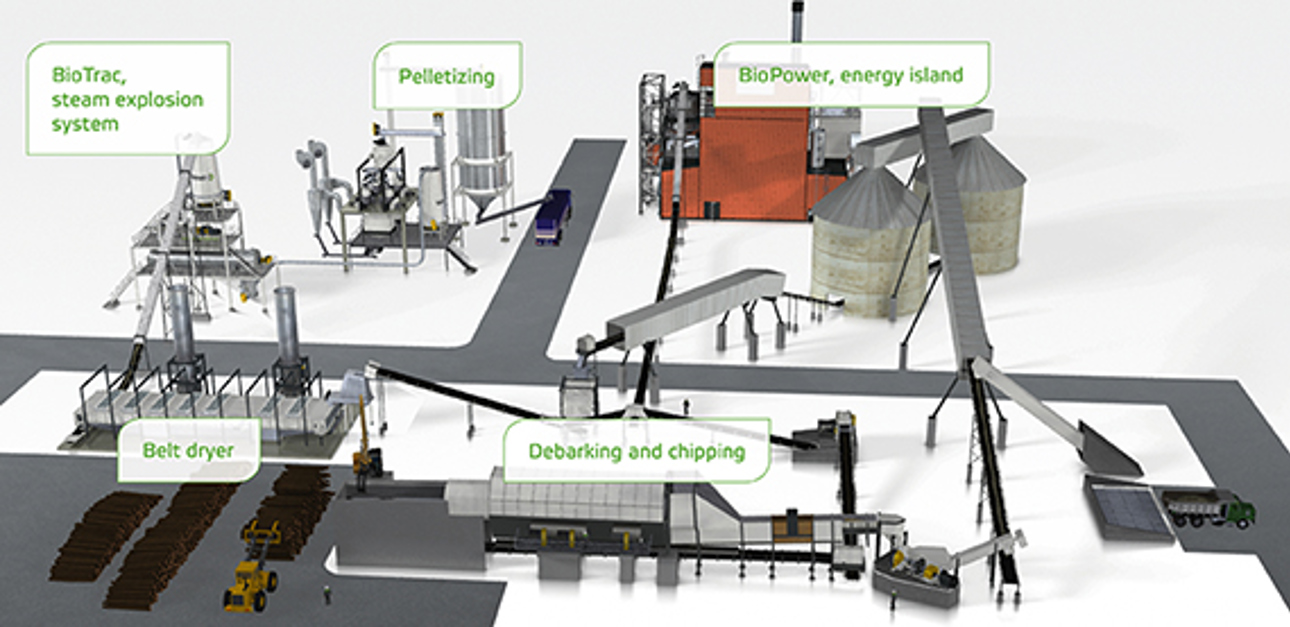

Black pellets are a type of renewable biomass fuel that can replace fossil coal in power plants, significantly reducing carbon emissions. Steam exploded black pellets are safer, more cost-effective, and deliver more energy than conventional “white” biomass pellets. Valmet can deliver a complete black pellet production plant, from infeed of raw biomass feedstock to output of solid biomass fuel.

Large amounts of renewable woody biomass feedstock are widely available across the globe at competitive prices. However, transporting this biomass feedstock to its final users is often inefficient, largely due to its high moisture content. This problem solved through steam treatment of the woody biomass followed by rapid depressurization. This process creates a low-moisture material that is perfect for producing durable, water-resistant pellets or briquettes. Such pellets are excellent for safe and long-distance transportation, allowing power companies to take advantage of the global abundance of raw biomass supply.

Minimizing capital expenditure

The solid biomass fuel produced in Valmet’s black pellet plant is steam exploded and can thus be ground into a reactive powder suitable for burning in large-scale power boilers or in specialized pellet-burning systems.Black pellets can thus replace fossil coal up to 100% in smaller units and up to 70% in larger units. The powder produced by grinding has a relatively high bulk density and is free flowing, meaning that it is ideal as a feed material to entrained flow gasification systems as well.

“Black pellets contain and retain more energy than white pellets. There is no self-heating or off-gassing and the low amount of dust minimizes the risk of fire hazards. They grind and burn more like coal than white pellets, which saves customers both capital and operational expenses” says Mattias Erixon, Senior Sales Manager at Valmet.

Black pellets are cheaper to ship than white pellets. This is due to the higher wet and dry durability of black pellets, as well as the fact that they hold about 15% more energy per ton and have 15% higher bulk density than white pellets. That gives savings of approximately 30% with black pellets compared to white pellets just in shipping, regardless of prevailing fuel prices. In addition, black pellets can be handled and loaded/unloaded in the rain. This is not an option with conventional white pellets, which immediately disintegrate upon contact with water.

Proven and safe technology

Valmet's steam explosion technology is based on decades of experience arising from numerous deliveries of projects to fiberboard and chemical pulping industries.

“We can offer a solid technical solution based on a reliable base, minimizing the technology risks of a steam exploded black pellets project”, Erixon continues.

Valmet’s technology is safe as the process is based on the use of steam, with no chemical additives such as binders for the densified product. The environmental performance is built to meet any local requirement by using our in-house experience and technologies for cleaning gas and water.

“Valmet offers both complete production lines for steam exploded black pellets and revamps of existing white pellet plants. These high-energy-density, water-resistant pellets are suitable for transportation and opens up opportunities for new income streams for our customers”, Erixon concludes.