Minimize CO2 emissions in board and paper production

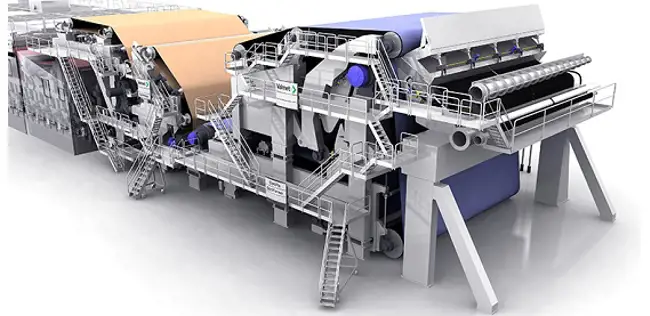

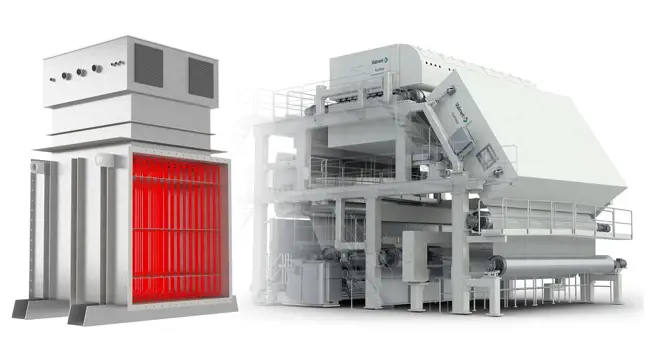

Innovative technology, the right services for reliable production, raw material and energy efficiency, fossil-free energy sources and circularity – they all help us fight against climate change and play a key role in the transition to a carbon neutral economy. Valmet’s target is to enable carbon neutral board and paper production by 2030 at the latest.

Towards even more sustainable board and paper making

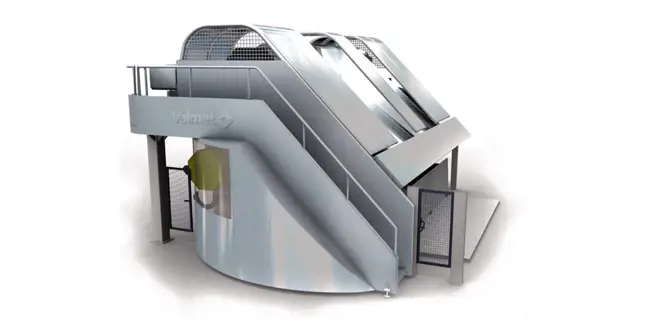

We offer unique solutions for reducing CO2 emissions and other environmental impacts in board and paper production through a combination of process technologies, services and automation solutions. With our long experience and innovative solutions, we can help you significantly reduce your CO2 emissions – as well as your operational costs.

A complete offering for board and paper makers

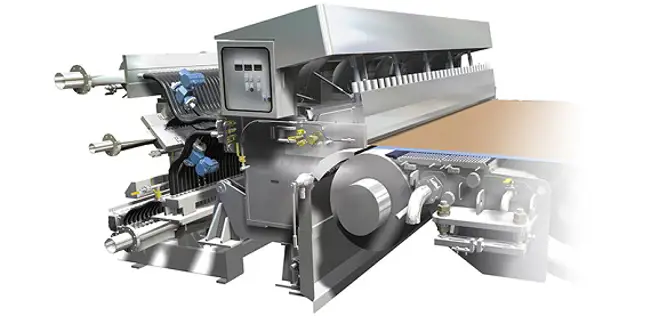

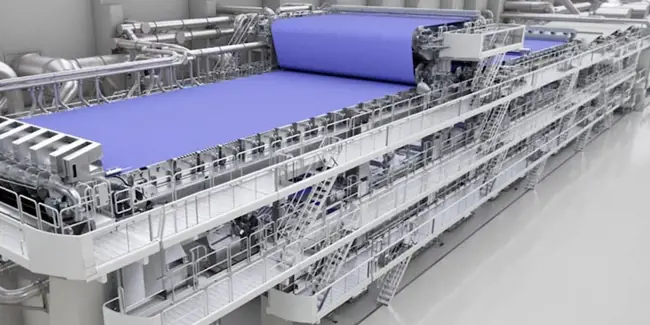

Our key objective is to enhance the competitiveness of our customers’ processes by improving the productivity and efficiency of their production lines and promoting sustainable paper production through the best available technology and innovative technological solutions.

Our comprehensive services and automation offering help to maximize the environmental efficiency of the technologies and ensure operational safety and reliability over the entire lifetime of the plant.

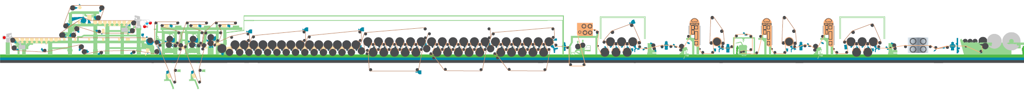

|

Electricity |

CO2 emissions |

|

-16 % |

-14 % |

Total saving potential for a paper machine. Calculations are based on an optimized coated board machine with the best available technology excluding stock preparation.

Want to reduce your environmental footprint?

Our experts can support you to find the most suitable solutions for your sustainability needs.

Contact our expertsImprove your sustainability with Valmet's services

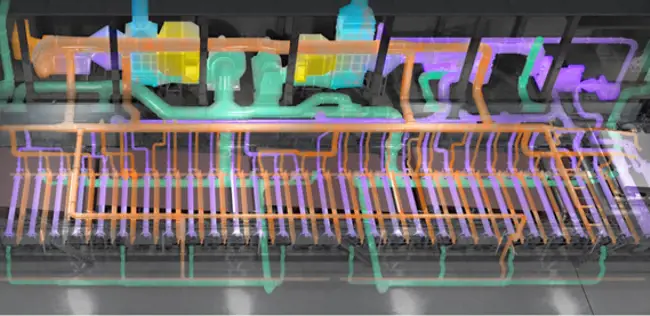

Valmet’s service expertise supports you in improving the efficiency of operations and stabilizing the manufacturing process throughout the life cycle, ensuring a minimized environmental footprint. By combining our experts’ long-term experience with yours, our cooperation enables continuous process optimization. This means improved energy efficiency, decreased raw material and water use, and thus lower operating costs for the desired output. In addition, our onsite and remote services support you in decreasing CO2 emissions, enhancing circularity, and ensuring the proper maintenance of your production equipment. It’s about the right services and solutions at the right time.

Explore solutions to minimize CO2 emissions

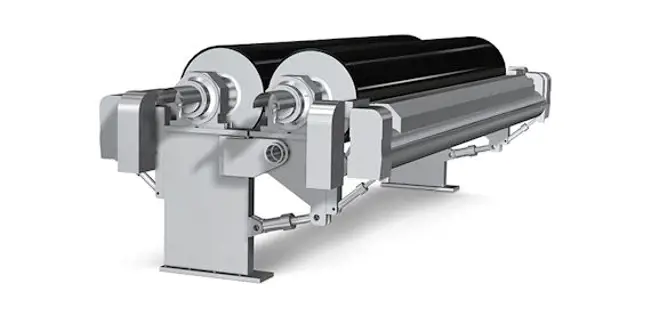

Nippon Dynawave: sustainable board with less CO2 emissions and fibers

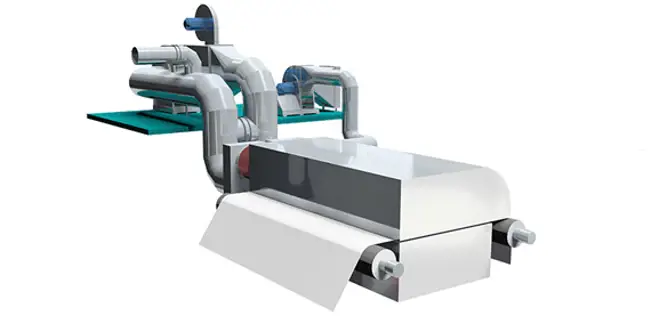

Nippon Dynawave wanted to go towards a more sustainable board production. They succeeded in reducing greenhouse gas emissions and using less fibers for the same amount of board with the Valmet-supplied metal belt calender. Watch the video to find out more!

Our sustainable solutions for board and papermakers

Explore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy