Coater backing roll showers - purpose, layout and setup

Showers on the backing roll are used to lubricate the blade and cool the roll where there is no sheet and to keep any coating from building up on the roll. This process will help extend the life of the roll, requiring fewer roll changes. These showers can be set up to also help reduce sheet breaks on or after the coater station.

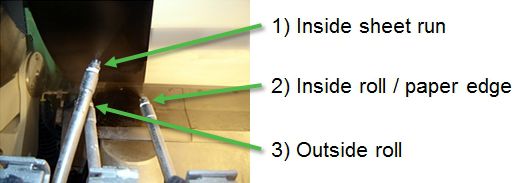

Coater backing roll shower location and orientation

Here is an example of how a new Valmet backing roll shower setup would function:

- Shower #1 is aimed to contact the backing roll inside the sheet path. This shower reduces curl, relaxes the sheet edge tension, and keeps the inside of the sheet path clean.

- Shower #2 is aimed to contact the outer 1-2" of the uncoated sheet edge and half of the exposed backing roll. If the incoming sheet has already been coated, you may not be able to rewet the coated surface as this could cause the coating to soften and buildup later down the line.

- Shower #3 contacts the outer half of the exposed backing roll.

The shower nozzle type varies according to the desired effect, and adjustment is tricky. A common mistake is to set the air too high and water too low. When installed properly by Valmet field service engineers, the coater backing roll shower system should last years, reducing sheet breaks and backing roll changes.

For more information about extending coater backing roll life, contact your Valmet representative.