Automation for Board and Paper

Optimize and automate processes to reach your production and sustainability goals

Did you know Valmet is the only board and paper machinery supplier that also provides a full-scale OEM automation system? Our solutions are based on decades of experience working closely with board and paper makers to optimize production end-to-end. Serving both greenfield and brownfield projects, big and small, our proven automation solutions enhance efficiency, quality and sustainability end to end, from stock preparation to converting lines.

Systems and Products

Together with our customers, Valmet finds the best possible automation setup. We proactively develop new machinery and control solutions for the paper and board industry that improve operational processes. We understand the connections between raw material quality, fiber properties, and board and paper final quality.

Our automation solutions not only serve paper and board production lines but also improve monitoring and controls of existing lines to improve machine line efficiency. Through intelligent automation, you get more out of your investments and gain a higher degree of control over final quality while saving material costs and energy.

Enable the path towards full optimization

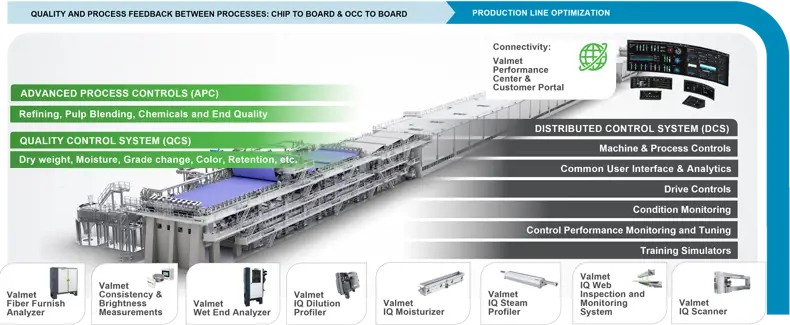

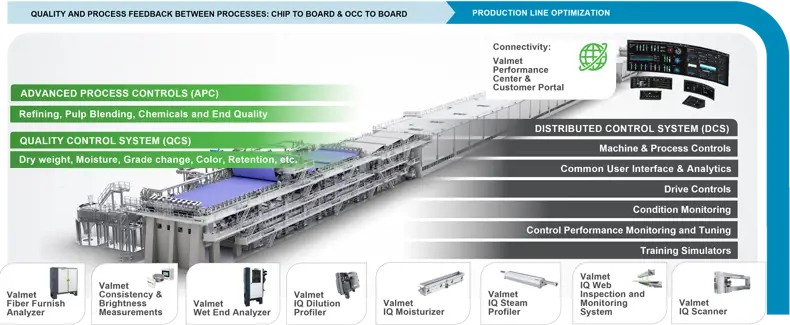

Digital, autonomous operations have become the guiding principle for board and paper producers worldwide. The journey towards full optimization starts with data. Our wide range of sensors and on-line measurements deliver precise data critical to board and paper making processes.

The process data is fed to Valmet’s intelligent analyzers which are integrated with the related process control loops. Production teams monitor and manage end-to-end through Valmet DNAe, a distributed control system that unifies all the data into structured, easy-to-understand information.

Valmet’s advanced process and quality controls combined with accurate, real-time data from the entire machine line significantly raises the potential for enhanced safety and efficiency, cost reductions, and lower environmental impacts.

On this image

-

1 Fiber Furnish Analyzer

-

2 Brightness Measurement

-

3 Wet End Analyzer

-

4 Valmet IQ Dilution Profiler

-

5 Valmet IQ Moisturizer

-

6 Valmet IQ Steam Profiler

-

7 IQ Web Monitoring System

-

8 High-speed scanners for precise quality control

-

9 Distributed control systems (DCS)

-

10 Process optimization

-

11 Quality control system (QCS)

Fiber Furnish Analyzer

Valmet Fiber Furnish Analyzer (Valmet MAP Q) provides paper, board, and tissue makers with fast and precise online updates of key fiber and papermaking furnish properties.

Brightness Measurement

Valmet Brightness Measurement (Valmet Cormec5 X) is primarily an in-line pulp brightness measurement but its features has been enhanced with a capability to measure fluorescence, the impact of optical brightening agents on pulp as well.

Wet End Analyzer

The Valmet Wet End Analyzer (Valmet WEM) is a modular online measurement solution that provides tissue, board and papermakers with all the key variables for effective wet end management.

Valmet IQ Dilution Profiler

Valmet IQ Dilution Profiler has been specially designed for achieving the best possible weight profile that a headbox can produce.

Valmet IQ Moisturizer

Valmet IQ Moisturizer is a moisturizing system with applications for profiling, curling and calendering.

Valmet IQ Steam Profiler

Valmet IQ Steam Profiler is the highest efficiency steam profiler family to increase production capacity, decrease energy consumption and improve moisture profile.

IQ Web Monitoring System

The newly enhanced Valmet IQ Web Monitoring System (Valmet IQ WMS) delivers unmatched performance for today’s demanding production environments. Designed for advanced process analysis, it enables operators to quickly identify and trace defect origins as they occur. With industry-leading illumination, sharper visuals and the most compact design available, it helps maximize product quality and efficiency across the pulp, paper, tissue, and paper & board converting industries.

High-speed scanners for precise quality control

At the heart of the Valmet IQ quality control systems are Valmet IQ Scanners. Featuring unique adaptive scanning capabilities, they can be used with a wide of range high-quality online measurements for precise quality control.

Distributed control systems (DCS)

Valmet DNA and Valmet DNAe are safe, future-proof distributed control systems built on your industry's leading process know-how. They empower your people to perform at their best, utilizing a unified user interface and sharing advanced data analytics from Valmet DNAe. With lifetime systems compatibility, step-by-step upgrades, and seamless migration from other DCS and PLC systems, you can unlock the full potential of your 24/7 operations for decades to come.

Process optimization

With Advanced Process Controls (APC), you can increase profitability by improving production capacity, lowering quality variations, and reducing operational costs.

Quality control system (QCS)

The Valmet IQ Quality Control System (QCS) is a highly customizable quality management solution that helps you increase process performance while meeting your quality goals.

Empowering everyone to succeed

Valmet provides complete automation solutions that optimize the entire production chain — from raw materials to end products. Through advanced control technologies and seamless system integration, we help board and paper producers achieve higher efficiency, consistent quality, and sustainable performance.

The DCS is the core of automated operations, including critical process and drive controls of the paper and board machine line. It provides a consistent, web-based user experience for monitoring process controls, optimizing targets, assessing equipment condition, generating detailed reports and more. Essential information is accessible from any device regardless of physical location.

With Valmet’s advanced control and optimization technologies, mills can achieve precise process control and smarter, data-driven decisions at every stage of production.

Measure and monitor everything that matters

Valmet offers accurate and reliable quality measurements and controls for the entire paper and board production line, end-to-end, form stock preparation and headbox, to forming, pressing, drying, sizing, coating, reeling, and winding. Our asset performance monitoring solutions help ensure equipment is working efficiently at every stage.

With measurements, controls and monitoring in place, you can automate and optimize the entire production line. Operations teams can work more efficiently with new insights that help them quickly and confidently adjust to production, quality and sustainability targets.

Stay in your optimal operational window

Your automation system plays an essential role in ensuring every asset is performing exactly as it should so that processes stay in your planned, uninterrupted optimum window of operation. Over quality is as costly as under quality, so your automation system needs to keep process in an optimum operation window with lowest possible variability.

Valmet’s distributed control system, Valmet DNAe, combined with high-precision analyzers, flawless low-level controllers, and advanced process controls, eliminates all possible sources of variability, from human operators to equipment and raw materials.

Intelligent, real-time adjustments compensate for changes in equipment behavior and raw material quality variations that impact fiber properties. This enables you to consistently do more with less, and with intuitive tools give you up-to-date reports on, for example, energy and chemical use, vital information is a glance away for data-driven decision-making.

A committed partner you can trust

Valmet’s decades of unparalleled experience in pulp and paper machines and automation are always available through our global service network. Through remote and local support, Valmet experts help to ensure you get the highest possible performance from your assets over their entire lifetime.

From smooth implementation to fast, reliable start-up and beyond, Valmet Services help train and support your teams. Together we make the right choices for your unique paper and board production operations, using predictive diagnostics and extensive experience with automation and process equipment performance.

Stay secure in a digitally connected world

Connecting and digitalizing production sites can create unwanted opportunities for cyber criminals. Control systems with remote access must be hardened against the growing threats against industries and their critical infrastructure.

Our paper and board automation solutions are developed following secure-by-design principles. Cybersecure from field equipment to control systems all the way up to plant-wide planning and optimization, Valmet systems provide peace of mind in a rapidly evolving world digital world.

Are you interested in specifications, prices and expert services?

Our experts are here for you and ready to discuss your challenges. Just answer a few questions and we will contact you shortly.

Contact usNews

- Dec 2, 2025Next-generation Valmet IQ Web Monitoring System sets a new benchmark for process visibility, quality and efficiency

- Nov 27, 2025Valmet to deliver advanced automation for the new Polarstern, enabling precision and sustainability in polar research

- Nov 26, 2025Valmet and SpecTec Cruise partner to streamline maintenance data flow for cruise operators

- Nov 25, 2025Valmet signs a two-year service agreement with FPC Tissue Spa to ensure optimal mill performance

- Nov 18, 2025Valmet’s automation solution for improved waste management and resource efficiency at the new South Korean incineration facility