Zawory do produkcji celulozy, papieru, kartonu i papierów higienicznych

Poprawa niezawodności, wydajności i wpływu na środowisko

Zawory wraz z regulacją przepływu odgrywają istotną rolę w procesie produkcji masy celulozowej, papieru, kartonu i papierów higienicznych. Przemysł dynamicznie sie rozwija i wymaga nowych, rozwiązań. Obszerne portfolio produktowe zaworów Valmet, wsparte innowacyjnym projektowaniem w połączeniu z doświadczeniem, pozwala rozwiązać największe wyzwania inżynieryjne naszych klientów w zakresie poprawy niezawodności, wydajności i wpływu na środowisko. Pionierskie rozwiązania firmy Valmet są wdrażane od początku istnienia przemysłu papierniczego dlatego dziś większość masy celulozowej na świecie przepływa właśnie przez nasze zawory.

Reliable partner

We are committed to helping manufacturers meet growing and changing demands and grab a hold of the opportunities.

Optimized process performance

based on real-time data can yield tangible results in terms of profitability.

Expert service

technical support and service in over 40 countries around the world.

Comprehensive portfolio

Industry’s most comprehensive portfolio of safe, reliable and high-quality flow control solutions.

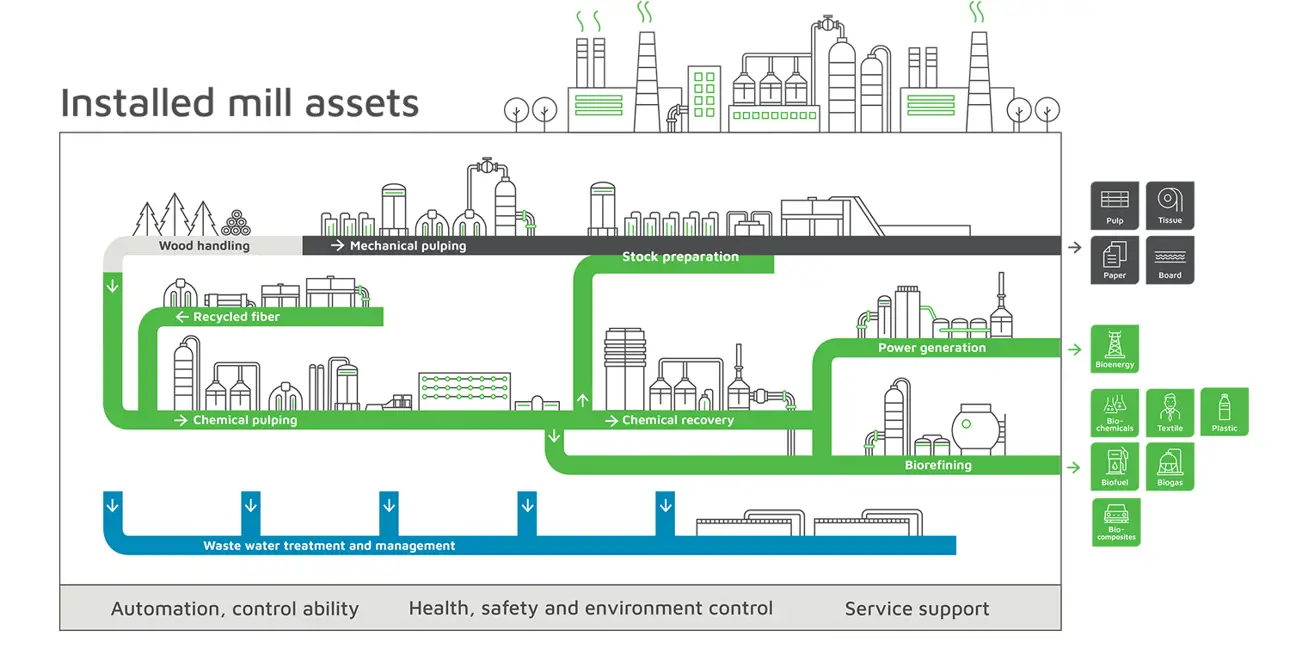

Pulp and paper industry is evolving

Global megatrends are transforming the pulp, paper and board industry as we know it. While demand for traditional printing and writing paper may have declined, thanks to steady population growth and the explosion of online shopping and international shipping of packaged commodities, the demand for tissue and board are pushing overall demand up every year. Intelligent control valves help optimize the flow of materials throughout the modern pulp and paper mills. A high-quality, stable process consumes less raw materials and optimizes energy consumption. These process attributes achievable with our valves save both money and the environment.

Towards sustainable success

Addressing sustainability concerns while ensuring profitability is a major driver for the development of more efficient production processes. How can better flow control drive the pulp, paper and board industry towards sustainable success?

We at Valmet are leaning on both our long-standing industry experience, comprehensive portfolio of valve and pump products accompanied by service expertise and the latest digital technologies to help our customers make more with less. Our valves are helping drive processes towards improved efficiency, reliability and environmental performance in the pulp, paper, board and tissue industry.

Results through optimization

Digitalization provides the tools needed to make the most of your process. Traditional pulp, paper, board and tissue processes can be improved by intelligent valves and real-time data. The service and added value we can bring to the table early on in the mill planning phases is based on our expertise and digital tools designed to help collect and utilize accurate data. The right digital tools can help significantly reduce the planning and engineering time required, while ensuring a process running with the best possible valves for the job.

Over a mills lifecycle, optimizing process performance based on real-time data can yield tangible results in terms of profitability. More stable flow characteristics ensure process efficiency and the even and predictable quality of the output. Accurate process control data also enables the effective planning of predictive maintenance operations, reducing the risks of valve failure and expensive unplanned shutdowns.

Reliable and experienced partner

We provide a strong presence across the entire lifecycle of your mill, from the first investment consideration to end of operational life. As long as your operations are up and running, we offer our expertise, knowhow, tools and devices to help you make the most of this new era in pulp, paper and bioproducts.

During the planning and engineering phase, we provide assistance in valve specification and selection, the digital tools for fast and easy design and engineering process, as well as the widest portfolio with all the application-specific valve products for the entire mill project.

For the mill owners and operators, we are a dedicated service and support partner across the mill’s entire lifetime. This includes maintenance, repairs and spare parts. But it also includes help with continuous process optimization and comprehensive lifecycle services.

Valves, valve automation and services for pulp, paper, board and tissue

Valves for paper and board machines

The biggest single expenditure in a paper and board mill is on energy consumption. That is why faultless valve operation has an important role in the steam and condensate system.

Valmet offers a wide choice of on-off and control valves for the steam and condensate system. Good tightness is a preferred feature for all steam valves. If accurate control is your concern, the R-series segment valve is the obvious choice. It will help you to adjust temperatures in the steam and condensate system fast and accurately, for example in a grade change situation. Furthermore, our cost-effective triple eccentric butterfly valves offer excellent tightness and good control properties for steam and condensate systems.

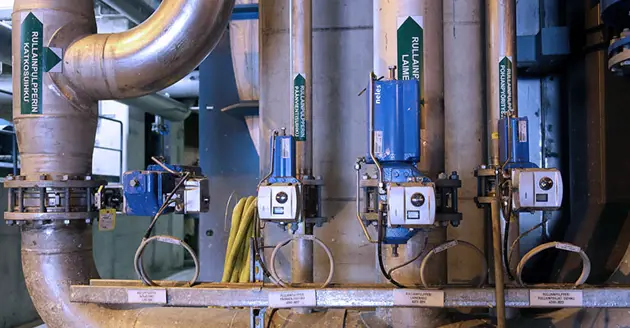

Valves for pulp production

Valmet's Neles™ valves have been used for over 65 years in fiber line applications. Our long history in chemical and mechanical pulping provides the right, reliable valve solutions for a wide variety of processes. Typically, a fiber line consists of the following subprocesses: wood handling, cooking, washing and screening, bleaching and drying.

Valves for tissue machines

High speeds and quality standards require a good ability to control the flows. When handling steam, large pipe sizes are often in place that require a cost-efficient valve selection. Also, the tightness of the steam valves is often an issue that jeopardizes the plant's energy efficiency. Another challenge is tissue additives, which can be hazardous to the environment or even toxic.

For flow control services, V-port segment valves are recommended. For large pipe sizes, cost-efficient triple eccentric disc valves are the right choice. Neles™ high-quality ball valves are recommended for applications that need extra tightness and reliability. Triangle-shaped, live-loaded packing can be installed into the shaft if toxic or environmentally hazardous chemical leakage is a problem.

Download brochure |

||

|---|---|---|

| Flow control solutions for pulp, paper and bioproducts brochure | ||

Application reports for pulp, paper, board and tissue

The best flow control solutions for an evolving pulp & paper industry

Valves play a vital part in pulp, paper, board and tissue production. As efficiency, reliability, sustainability, safety and profitability demands on the processes themselves have grown over time, the valve technologies too, have developed immensely.

Read the article