How does your business sound like? Hopefully, there are no vibrations, annoying breaks or disturbing shutdowns

Valmet Rolls and Workshop Services is a winning combination of the latest technology and rock-solid maintenance expertise. We help you eliminate unplanned shutdowns, increase the running times of rolls and equipment and improve the end product quality.

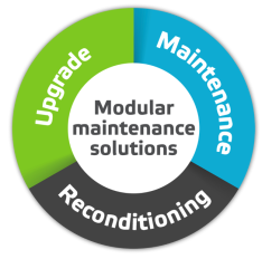

The wide selection of services extends from roll reconditioning and new roll technology to upgrading and reconditioning of pulp & fiber line equipment, as well as efficiency projects and preventive maintenance. For every mill in the world, we have a specialist near to you in our +25 Roll Service Centers.

Just contact us, and let the good times roll into your production.

|

Benefits with modular maintenance solutions

|

Our responsibility of providing excellent service extends to the reconditioning, upgrade and additional service for feeders, refiners/defibrators and TwinRoll presses. Customized service combinations the use of latest Valmet technology, are the key factors for reliable processes and extended lifetime.

|

Reconditioning services include

|

Intelligent Roll Solutions will turn your roll into an intelligent service platform, providing a new way to analyze data and network globally. This data beyond the rolls can help you achieve your production targets for enhanced efficiency and cost savings.

|

What you can achieve with Intelligent Roll Solutions?

|

Clear and visual overview to your roll population

Valmet Asset Manager is a web-based system which contains all critical roll-related information in one place. It includes, for example, up-to-date roll status and location information to indicate where each roll is in given time frame, availability of spare rolls and running period statistics.

Valmet Asset Manager is an easy-to-use tool for mill-wide information sharing.