Quality management for self-adhesive laminating process

Producers of self-adhesive label stock face a number of quality problems originating not only in the converting operation but also with release liner and face materials that often originate from outside suppliers. Valmet IQ is an advanced quality control solution that can provide ideal conditions for the self adhesive laminating process and optimize as well as verify final product quality. New sheet quality measurements, innovative moisture profiling as well as web monitoring and inspection systems help reduce production costs, enable faster time to specification and reduce waste.

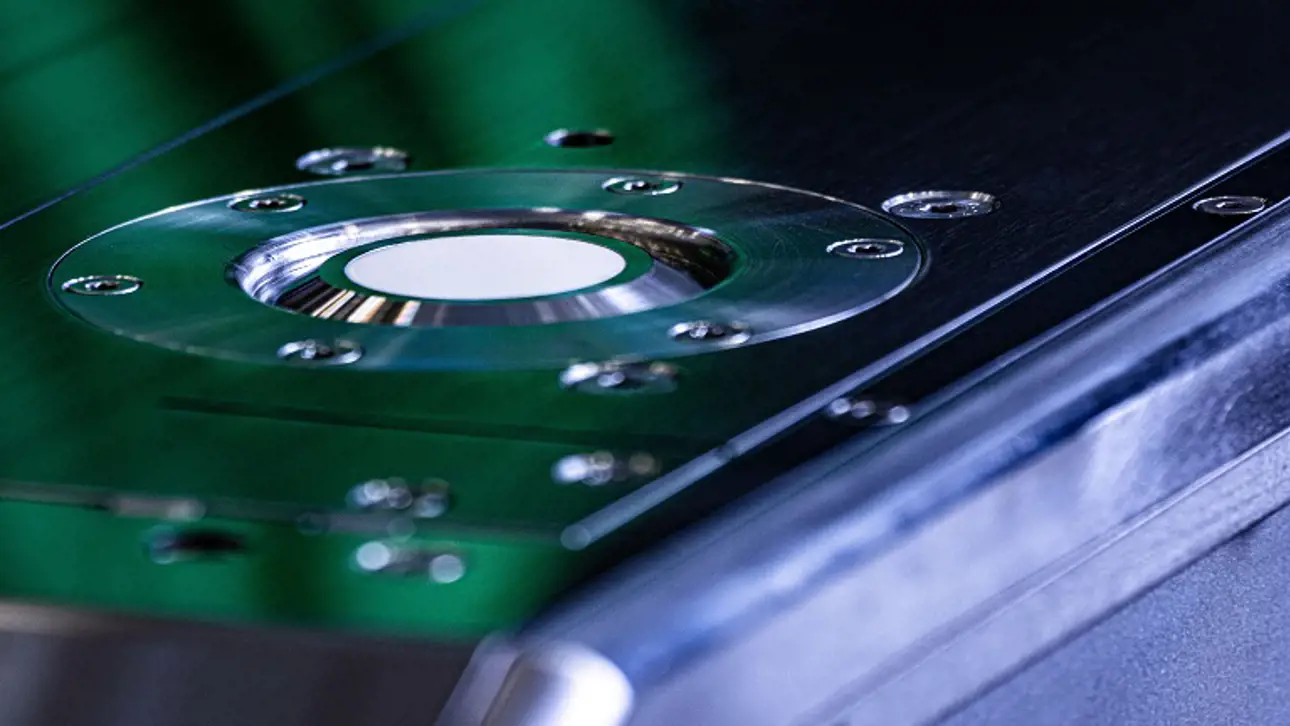

Silicone and adhesive coat weight measurement

Ensuring that laminate layers can be removed quickly and steadily is one of the main targets for self-adhesive laminate makers. The Valmet IQ Silicone and Adhesive Measurement and Valmet IQ Converting Scanner are designed for self-adhesive laminating applications to measure the correct coat weight amount precisely. Patented measurement technology enables high-resolution cross direction profiles of all silicone and adhesive types.

Curl elimination

To ensure smooth laminate processing across the whole value chain it is essential that the laminate stays flat. Valmet IQ CD/MD Multivariable Controls together with Valmet IQ Moisturizer and existing drying elements keep the backing and face materials in needed moisture level, providing flat laminate in all circumstances. With IQ Controls the final laminate stays flat after each speed and grade change or other process change.

Carbon-free production

Carbon-free self-adhesive laminate production without conventional steaming devices is possible with Valmet IQ Converting Moisturizer. IQ Moisturizer's patented extra-fine air-water spray mist technology provides needed moisture increase for all types of paper-based backing materials in all machine speeds and process conditions without steam. The capacity of IQ Moisturizer is up to five times higher compared to conventional systems, making it an excellent choice for high-speed lines, too.

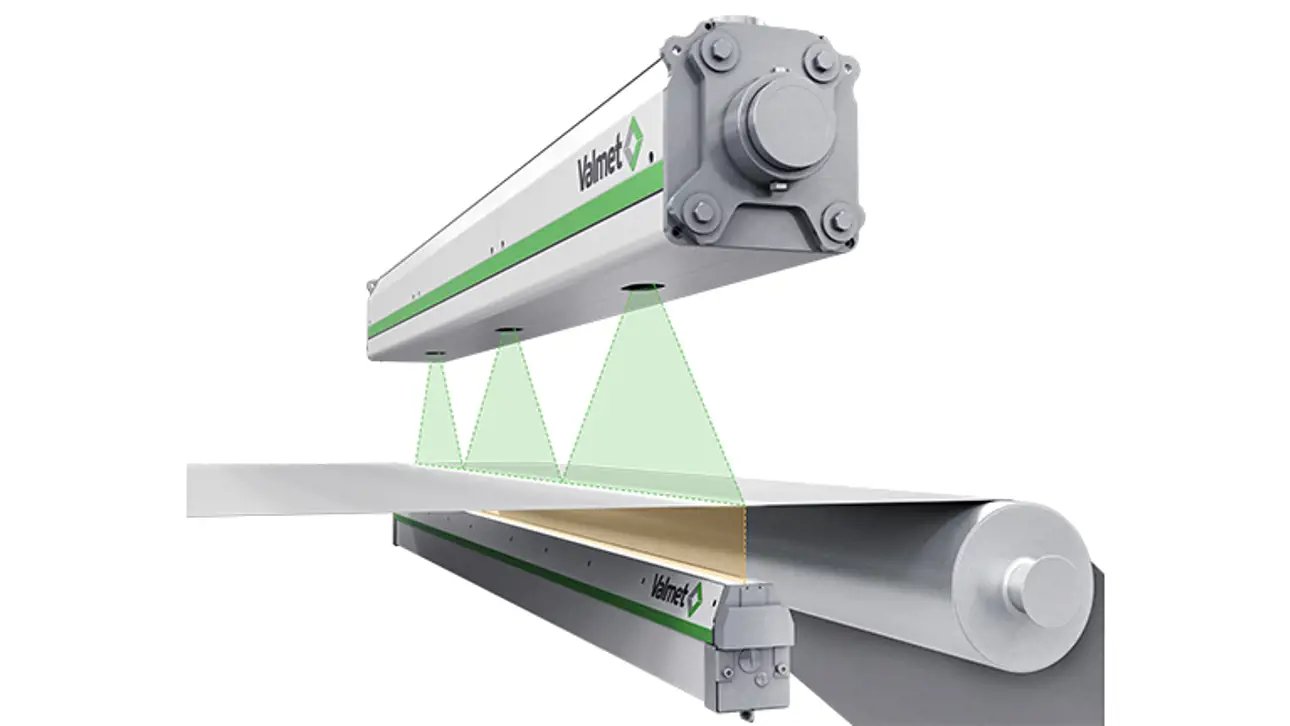

Ensure high-quality laminate production with instant feedback

It is essential to get instant and accurate feedback from the self-adhesive laminate process if the process equipment is not functioning well or raw materials are changing. Valmet IQ Web Inspection and Web Monitoring systems offer a solution for adhesive, face material and final laminate.

Awareness beyond the control room

Valmet DNA User Interface features an advanced operating concept where the walls of the control room are not the limit any longer. Based on the latest HTML5 standards, it allows working simultaneously on mobile and desktop devices. This opens new opportunities to access the process anywhere, anytime. Data from the online quality measurement and WIS can be combined and reported together opening deeper insight into the process.