OptiFormer Gap with shoe and blade technology

Innovative gap forming technology yields excellent results

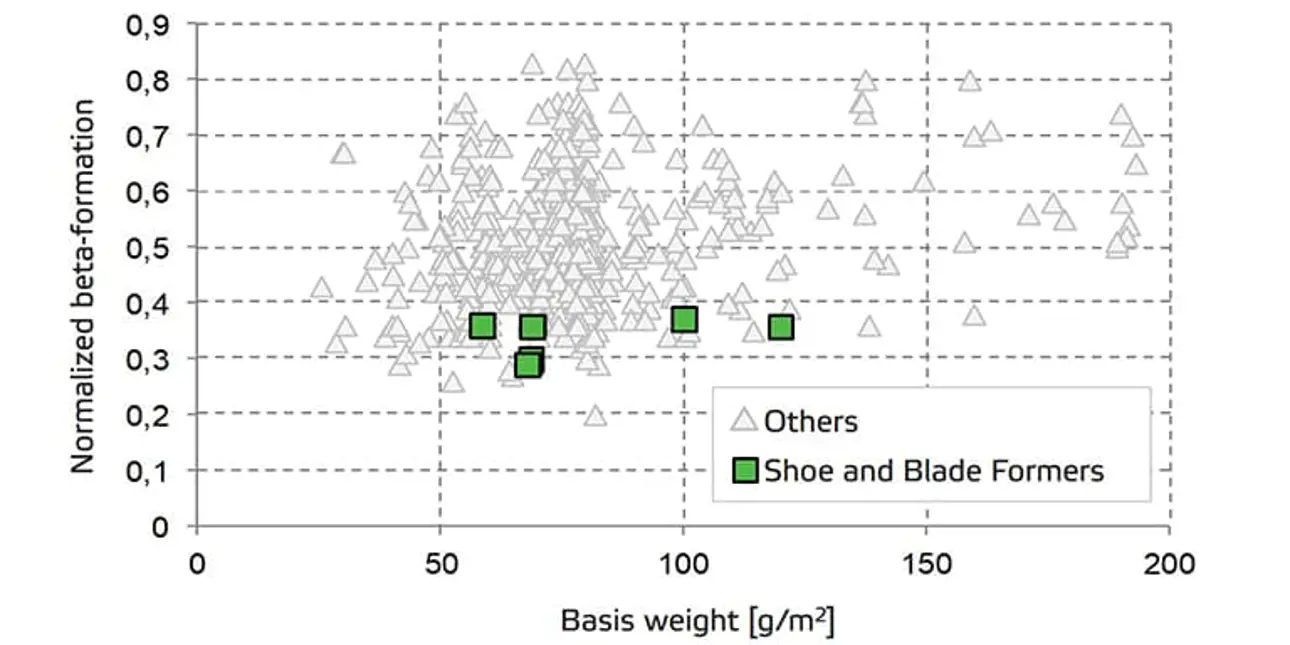

Valmet’s novel gap forming technology OptiFormer Gap utilizes innovative shoe and blade technology to gain superior paper quality. This new concept has been studied extensively on the pilot machine scale, and results from several running production machines compare very well with the pilot results. The formation has beaten all other references.

Good strength properties and uniform CD profiles

Adjustability and cleanliness at a new level

Uniform visual appearance of the end product

High-speed potential and excellent formation

Excellent formation in a wide basis weight range

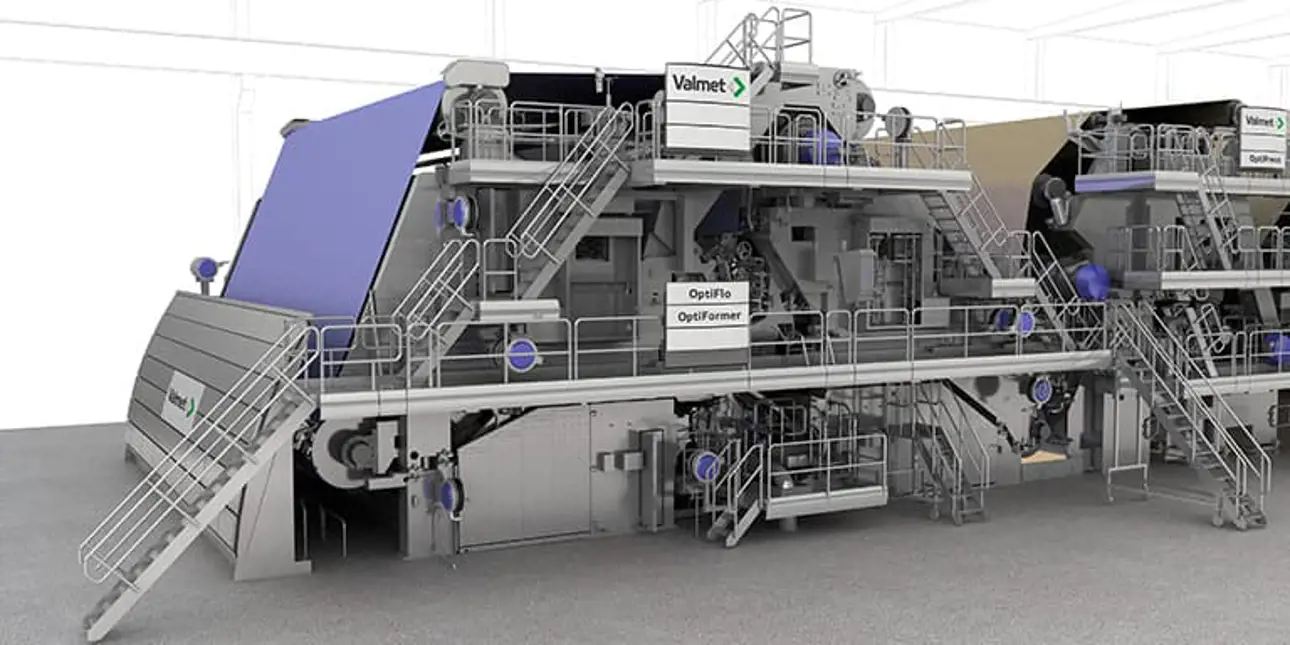

Initial dewatering of OptiFormer Gap takes place under non-pulsating conditions utilizing Valmet’s VacuShoe technology. Water is removed in the VacuShoe chamber area (jet landing area) through both the inner and outer fabric producing good retention and symmetric filler distribution at high filler contents in the paper. This very gentle initial dewatering of shoe and blade technology with stabilized jet impingement and minimized free jet length enables an exceptionally wide operating window.

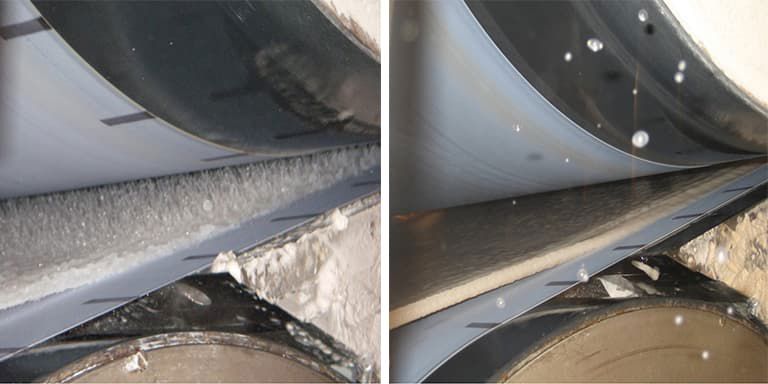

Non-optimized headbox slice geometry (left) versus optimized headbox slice geometry with OptiFlo Gap headbox (right).

After the paper surfaces have been formed, the dewatering continues in the blade dewatering phase, where the loading elements generate pressure pulses and shear forces inside the sheet. This finalizes the excellent formation and high dewatering capacity.

Dry content after the forming section ranges from 22% to 25%. This sufficiently high dry content after the forming section secures good runnability of the sheet at following process stages, e.g. dewatering control at the 1st press nip.

OptiFormer Gap with shoe and blade technology provides excellent end-product quality. A formation comparison (based on production machine data) of different forming methods. Grade: fine paper. Speed over 1800 m/min.

Want to talk to our forming section experts?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

send an inquiryShoe and blade technology: adjustability and cleanliness at a new level

Forming section with shoe and blade technology can be operated with a variety of grades without having to readjust the forming parameters. A shoe and blade technology allows completely free adjustment of the slice opening, jet/wire ratio, and the jet landing point without causing any sheet disturbances.

OptiFormer Gap with shoe and blade technology ensures excellent runnability through improved cleanliness in the gap area. Unlike the traditional forming section with a forming roll, possible dirt particles are trapped between the fabric and closed roll, but because dewatering happens in the stationary shoe area, dewatering removes dirt from the fabric surface causing no light spots on the paper. Closed breast roll surface also reduces the amount of misting around the headbox slice area. Therefore the top and bottom slice areas are very clean and dry.

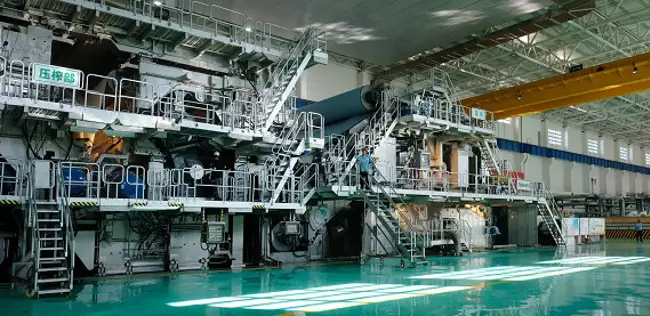

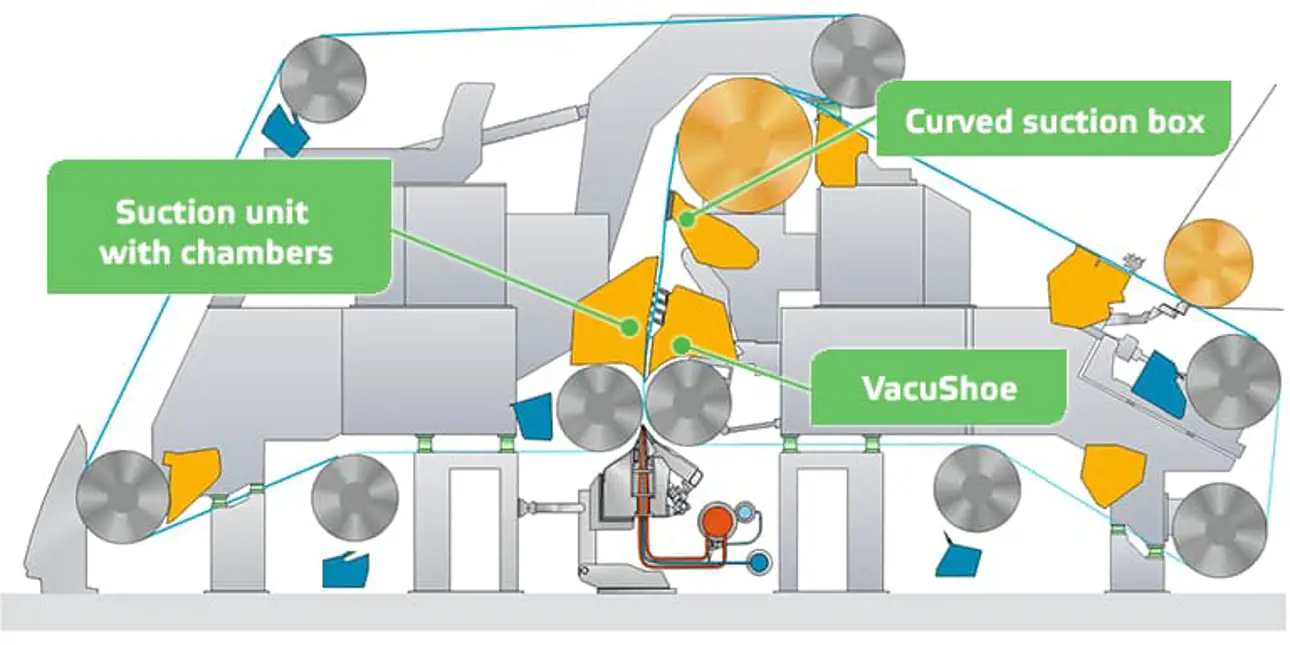

Key components of OptiFormer Gap with shoe and blade technology. OptiFormer Gap with shoe and blade technology is well suited also for rebuilds.

See the shoe and blade technology in action

The video displays the shoe and blade technology in Valmet forming sections with both paper and packaging grade applications. In addition, we show multiple different forming section layout options where shoe and blade technology has been used.

Looking for forming fabrics?

Valmet has constantly improved their forming fabric technology and created fabrics providing excellent runnability, high wear resistance, long running time, good paper profiles and good retention. Specialized forming fabric designs for packaging grades continue to improve drainage.

Read moreHow to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-bookPlanning a grade conversion?

The world is changing fast; the consumption of newsprint and printing paper is decreasing and the consumption of containerboards or cartonboards are increasing. An old paper machine can be updated with a grade conversion rebuild to produce more profitable products. Turn a new page for your paper machine with the help from Valmet.

Discover moreExplore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy