Valmet BFB Boiler

Valmet’s boiler solution utilizing bubbling fluidized bed (BFB) combustion technology is called Valmet BFB Boiler (formerly HYBEX). Wide fuel flexibility, high combustion efficiency, high reliability, excellent controllability and low emissions have turned it into a real winner, with over 200 new deliveries and boiler conversions around the world.

Fuel flexibility - from biomass to sludge and recovered fuel

Valmet BFB technology enables a combustion efficiency of over 99%

High reliability - proven design with Hydro Beam floor

Low maintenance costs - robust construction, no moving parts

Efficient combustion ensures low NOx and CO emissions

Wide thermal capacity range from 20 to 400 MWth

Straightforward design and proven technology

Valmet BFB Boilers are available in the size range of 20 to 400 MWth. Their proven technology and design ensure excellent combustion results, as well as minimal unplanned shutdowns and maintenance.

With Valmet BFB Boiler, you can count on high combustion efficiency of over 99%, resulting in boiler efficiency typically around 90% even with high moisture fuels.

For renewable biomass and various recycled fuels

One of the advantages of the boiler is the possibility to use fuels with high moisture content and low heat value. Typical such fuels include wet biomasses and different types of process sludges.

Dry biomass is suitable fuel as well and references are ranging between 15 to 65% moisture content.

Many boilers have a wide variety of fuels and the mixture may contain biomass and recycled fuels. Typical recycled fuels are recycled wood, recovered industrial waste and even processed municipal waste (RDF).

A BFB concept for 100 percent agro-residue fuels

One of Valmet’s long-term development projects has been the Valmet BFB Boiler for agro-residue fuels. It can run on high-alkaline fuels like wheat straw, sunflower husk empty fruit bunch and rice straw – fuels that were previously unsuitable for BFB combustion. The concept has been piloted at Valmet’s Energy R&D Center.

The main issue in fluidized bed technology using high-alkaline fuels is bed agglomeration. It can now be prevented with Valmet’s advanced combustion principles. Another risk for bed sintering with agrofuels is heavy furnace fouling. We have a patented solution for a furnace arrangement using two-zone combustion to keep the bed fluidized without disruption. The new BFB concept may apply to a new BFB boiler, or a boiler rebuild.

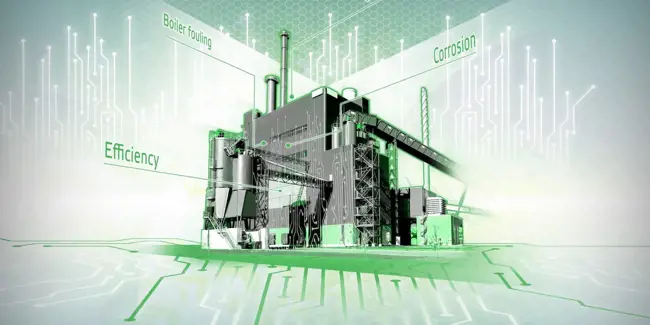

Efficient control of flue gases

The BFB combustion principle is based on the fluidization of a sand bed. The hot bubbling sand and solid fuel are mixed together in the lower part of the furnace. The high heat capacity of the sand bed ensures fast fuel combustion and absorbs fluctuations in fuel quality.

The fundamental core of the Valmet BFB Boiler is the patented Hydro Beam grate. It enables efficient and reliable removal of impurities and coarse material from the bottom of the furnace. Over 30% of the rigid water-cooled grate construction area is open for easy removal of ash from the bottom.

Flue gas emissions are controlled with carefully designed Valmet in-house solutions, including the combustion air system, SNCR or SCR systems, electrostatic precipitators, fabric filters with additive injection and flue gas condensing scrubbers.

Our unique offering

Our expertise is at your service

Our focus is to bring your performance forward. Our expertise in sustainable energy production is at your disposal. Get in touch with our specialists through your local Valmet office, or the link below.

Contact us