Material efficiency

Want to reduce your environmental footprint?

Our experts can support you to find the most suitable solutions for your sustainability needs.

Contact our expertsDecrease paper machine production costs

Material efficiency is part of sustainable development, and taking it into account is now more important than ever due to the growing scarcity of natural resources. Material efficiency covers the minimization of raw materials used in the production process, selection of the most economical raw materials possible, and the reduction and recycling of waste to minimize the amount of unutilized material.

Why is material efficiency so important?

Raw material is a major cost factor for pulp and paper mills since raw materials represent about 50% of total operating costs. It also provides an opportunity to boost profitability by minimizing the amount of waste, and related costs. By minimizing waste and recycling waste material, producers are able to meet global agreements and environmental protection goals, and thus help to promote sustainability.

Minimized use, maximized lifetime

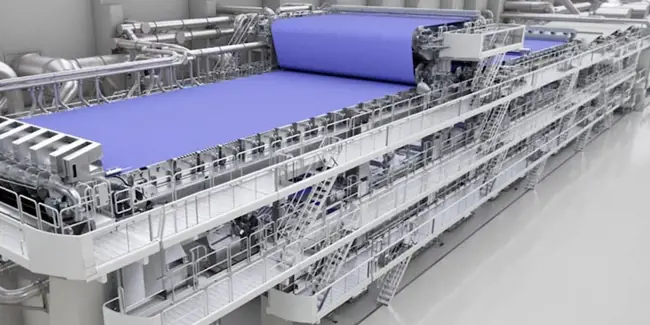

Valmet’s material efficiency solutions help pulp and paper mills to save raw material costs by minimizing the use of expensive raw materials (e.g. bulk-saving solutions at the press and drying sections and calenders) and reducing the consumption of chemicals (e.g. Valmet OptiDeink Flotation).

Maximizing the lifetime of consumables through optimized design (e.g. Valmet Refiner Segments, Valmet Seal Strip Flex, or coater blades) and reusing reconditioned equipment (e.g. refiner reconditioning and refiner exchange program) helps to cut equipment costs. Recycling such consumables as doctor blades and rod beds also save money.

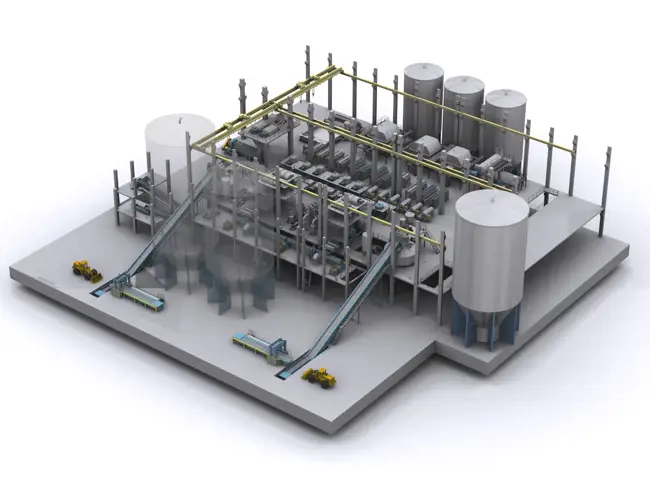

Our new modular machine concept, OptiConcept M, shows how all-around materials use optimization reduces construction costs and space needs, as well as saves energy and raw materials. This optimized compact paper machine design reduces frame weight and the environmental impact of the machine significantly.

Explore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy