Energy efficiency solutions

Want to reduce your environmental footprint?

Our experts can support you to find the most suitable solutions for your sustainability needs.

Contact our expertsWays to lower your paper machine's energy costs

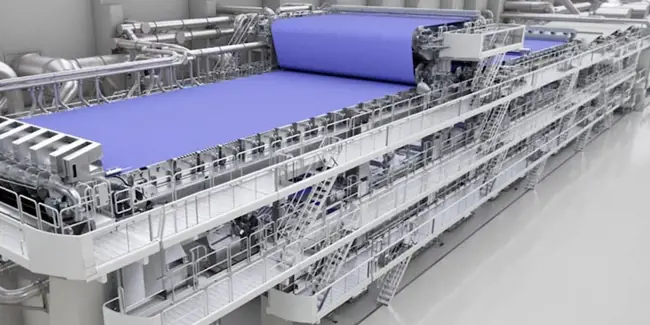

A shift to more energy-efficient and less polluting technology is vital. High energy efficiency offers an effective way to save costs and increase profitability – especially with today’s rising energy prices. Energy costs account for approximately 30 percent of total operating costs in the papermaking industry. Paper mills need to improve their energy efficiency in order to reduce their CO2 emissions to meet tightening environmental requirements. By consuming less, you not only boost your profitability but also save the environment, and can thereby look forward to a more sustainable tomorrow.

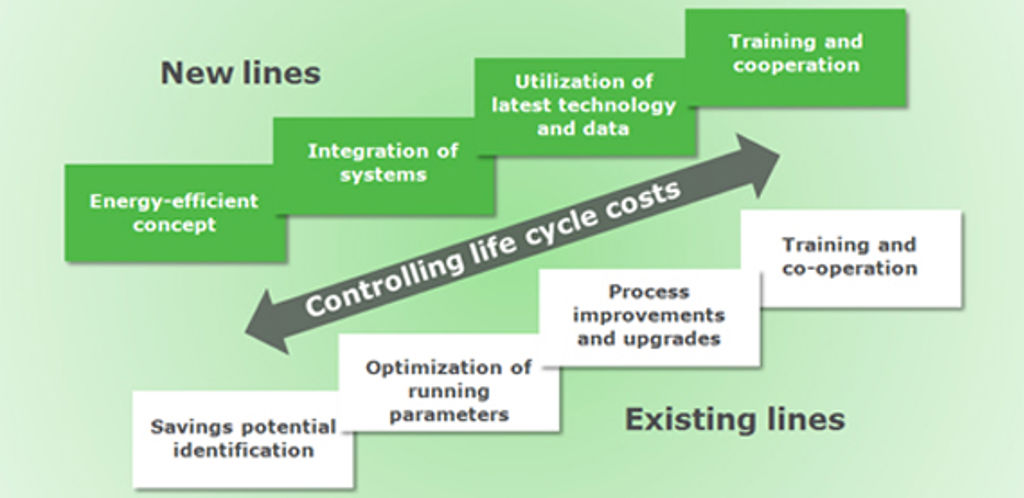

Minimize the lifecycle energy costs with the latest technologies and services

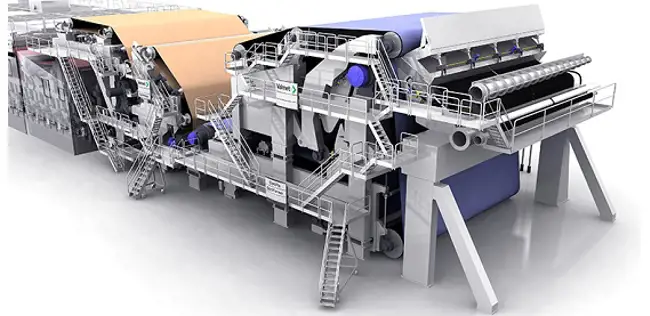

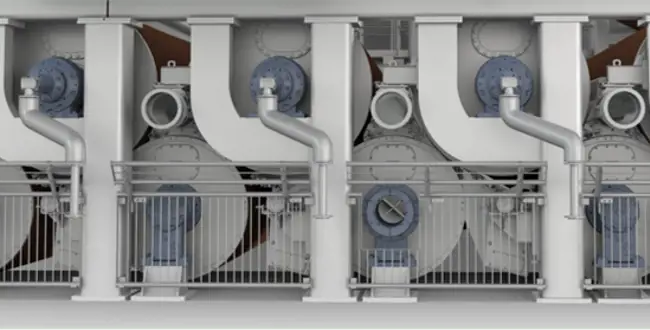

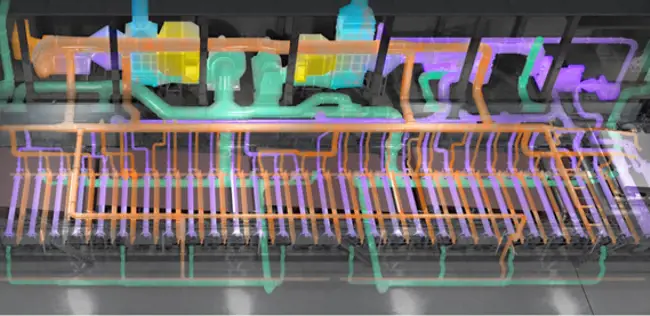

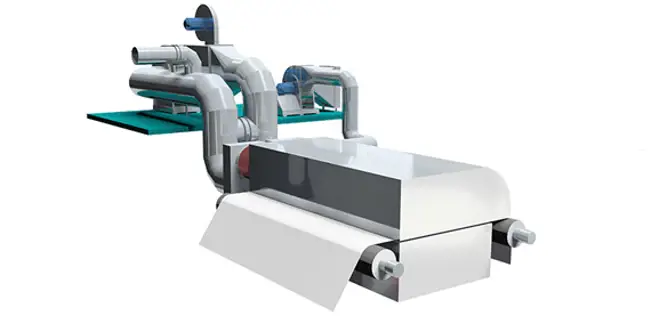

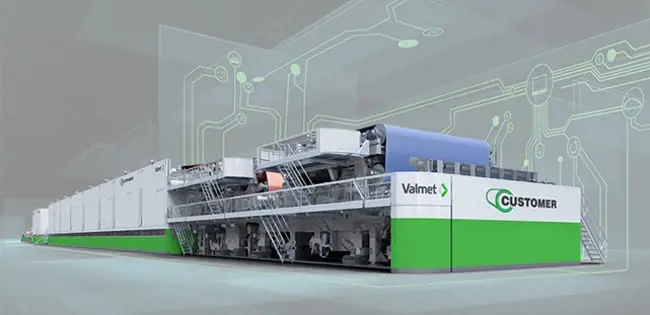

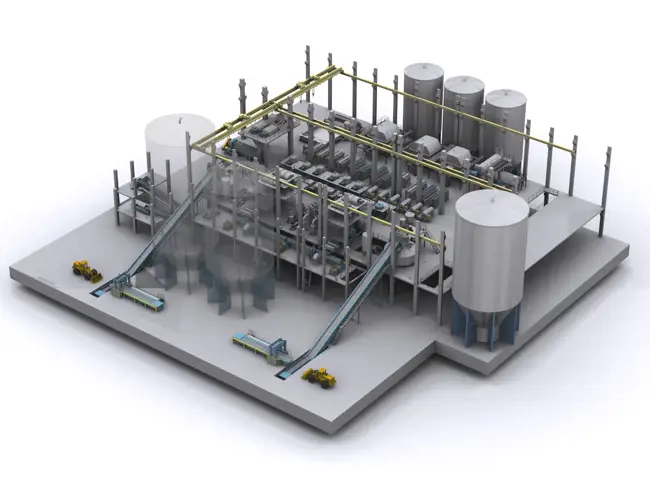

Valmet has numerous ways to help paper and board makers improve their energy efficiency and minimize their lifecycle energy costs. Individual energy-efficient components will not create an energy-efficient paper machine if they are not all working together. Valmet has the full palette needed from papermaking technology and equipment to auxiliary processes and automation. We understand the requirements and dimensioning of machines, and how to control them in an energy-efficient manner under various running conditions.

Our energy-efficient solutions for paper and board mills cover:

Steps to energy savings.

Explore solutions to improve your energy efficiency

Read more about energy efficiency

Want to keep your costs down?

How to use Industrial Internet to reduce energy consumption and keep costs down?

Learn moreExplore our latest board and paper press releases

- Jan 11, 2024Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

- Oct 25, 2023Valmet has received a major order of multiple technologies from Liansheng Pulp & Paper in China

- Oct 4, 2023Valmet introduces a new rotating consistency measurement for pulp and paper producers

- Sep 26, 2023Valmet to supply a fine paper making line to Yueyang Forest Paper in China

- Aug 31, 2023Valmet to supply key pulp and paper technologies to Naini Papers in India

- Jul 19, 2023Valmet to supply a high-capacity winder to Gascogne Papier in France

- Jul 4, 2023Valmet to supply an OptiFlo headbox and Valmet Conical Refiners to Shree Ajit Pulp and Paper Limited in India

- May 8, 2023Valmet to rebuild ITC’s board machine in India

- Apr 25, 2023Valmet to deliver key technologies for Henan Longyuan Paper’s testliner line in China

- Mar 27, 2023Valmet to supply a new container board making line to DS Smith in Italy