Highlights from previous issue

Pulp

- Complete pulp mills

- Chemical pulping

- Wood handling

- Cooking and fiber line

- Pulp drying and baling

- Chemical recovery

- Air emission control

- New value-adding processes

- Dissolving pulping

- Mechanical pulping

- Recycled fiber

- Fiberboard

- Flow control for pulp

- Services for pulp

- Automation for Pulp

- Industrial internet

- Sustainability for pulp

- Fiber technology center

- Pulp references

- Pulp news and stories

Board and paper

- Recycled fiber

- Stock preparation

- Sustainable board and paper production

- Project execution

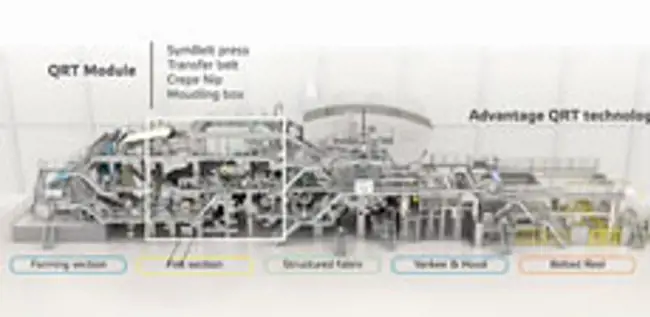

- Board and paper machines

- References

- Board & paper news & stories

- Services for board and paper

- Service Centers

- Search for products & services

- Automation for board and paper

- Flow control for board and paper

- Industrial Internet

Energy

- Energy solutions

- BFB Boiler

- CFB Boiler

- Gasifier

- Pyrolyzer

- Power plants

- Heating plants

- Air emission control

- Rebuilds and conversions

- Industrial Internet solutions

- Services for energy

- Automation for energy

- Flow control for energy

- Technology development

- Energy news and stories

- Sustainability for energy