Process upgrades for board and paper makers

Improve the production performance with board and paper process upgrades

Cost effective way to reach new board and paper production targets

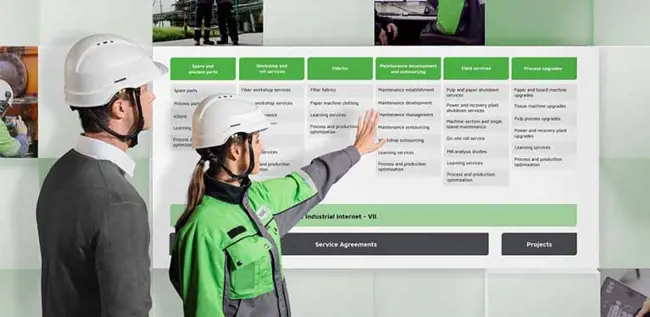

How to maintain the competitiveness of your core processes and to develop them throughout the lifecycle? We provide a wide range of solutions for upgrading and enhancing processes and machinery. The scope is always based on your specific needs and the solutions are tailored to maximize the performance of machinery processes.

As a leading technology expert in board and paper we have extensive expertise and experience. This knowledge is incorporated in all our products, giving us exceptional insight into all aspects of upgrading processes and machinery.

Small investments to remove bottlenecks

Upgrades are small or mid-size investments which removes production bottlenecks or extends the original process design limitations. Typical process upgrade building blocks are design engineering, new components, rebuild and upgrades and process controls and efficient commissioning and start-up service.

Read more about the process improvements and upgrade opportunities with refining, screening, headboxes, formers, press section, dryer section, winders, quality, vacuum systems, tail threading and cleaning.

Do you want to know more about process upgrades?

If you wish to get further information like technical specifications, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact usIs the new starch cooking unit part of your operation?

We have developed Enzymatic Starch Cooking ZE (zero effluent) to improve operational reliability and quality of the starch cooking process. The system has a smaller carbon footprint – thanks to improved design – as it uses less wasted starch compared to conventional cooking process. The built-in heat recovery is utilized in integrated hot water preparation, resulting in energy savings and decreased load and cost for water treatment.

Click here to read more about our latest installation

References and articles