Experience control at every level

Valmet DNAe

the next-generation Distributed Control System

Latest news

- Apr 16, 2024Valmet to deliver a boiler rebuild to E.ON’s power station in Scotland, the United Kingdom

- Apr 11, 2024Valmet renews its sustainability reporting

- Apr 9, 2024Valmet reaches a significant milestone for automation systems business by launching Valmet DNAe, the next generation Distributed Control System

- Apr 4, 2024Publishing of Valmet's Interim Review January – March 2024 on April 24, 2024

Explore our recent references around the world

Industries we serve

Pulp

Valmet’s fiber technical know-how provides intelligent, integrated and complete processes for both chemical and mechanical pulping. Our portfolio is built on strong R&D to guarantee high end-product quality. For improved process efficiency and increased business profitability, turn to Valmet. We offer intelligent automation solutions and services for the pulping industry, with solid experience and references.

Read more

Board and paper

Valmet’s expertise is rooted in experience. We’ve been co-operating with our customers in more than 700 board machine and 900 paper machine deliveries worldwide. Our offering includes everything for profitable board and paper production: innovative technologies, reliability and performance adding services as well as advanced automation solutions to guarantee that your paper machine runs smoothly, energy-efficiently and uses raw materials economically.

Read more

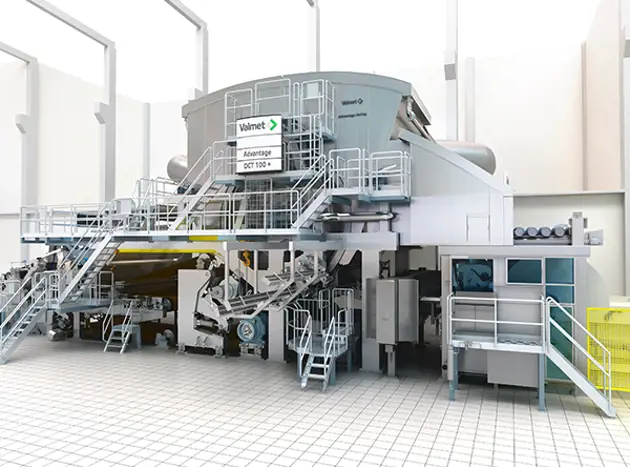

Tissue

Valmet's flexible tissue making technology provides sustainable production of all types of grades from plain to textured and structured tissue products with high quality. But we are not only limited to be a supplier of innovative solutions for the entire mill. We support you in planning, realization, installation and training as well as during the entire life cycle in order to make sure the mill operates at its optimum over the years.

Read more

Energy

Valmet is a reliable technology partner in the ever-changing energy markets. Based on our decades-long experience, we have the know-how to deliver energy solutions based on biomass, waste or on a mixture of different fuels. Together we can develop innovative, tailored solutions from our wide technology, automation, and services offering.

Read more

Valmet's climate program − Forward to a carbon neutral future

Valmet's climate program − Forward to a carbon neutral future − includes ambitious CO₂ emission reduction targets and concrete actions for the whole value chain, including the supply chain, our own operations, and customers’ use of our technologies.

Read more

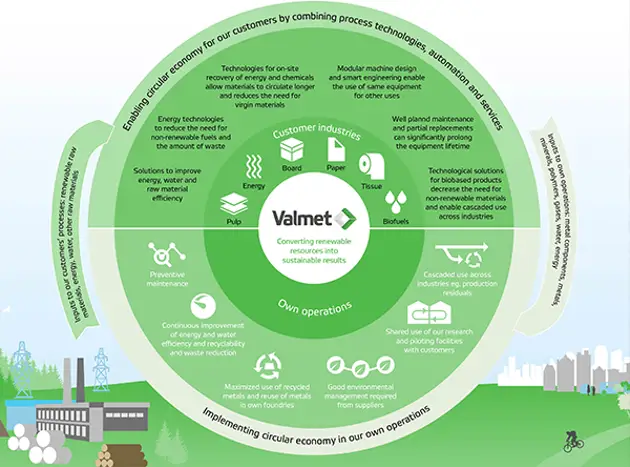

Taking the circular economy forward

Valmet is well positioned regarding circular economy. With our technology and services, we enable our customers to produce sustainable products from renewable materials and at the same time we continuously develop our own processes.

Read more