Steam recovery

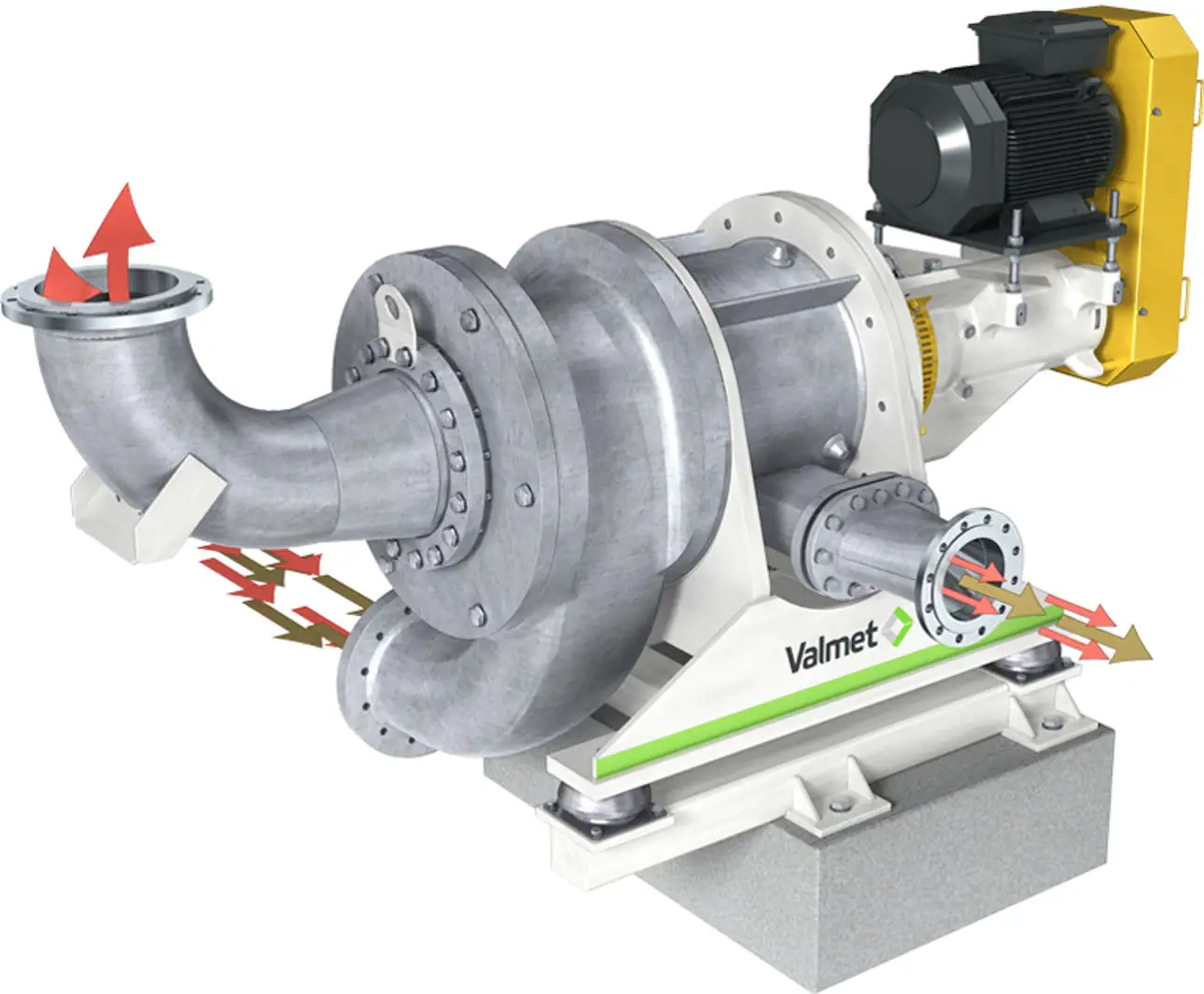

Valmet has experience with steam separation in many processes since the 80’s. With this experience Valmet has developed a steam separator for the recovery of steam in the Defibrator system. Valmet Steam Separator PV is a mechanical steam separator that separates the steam from the fibers efficiently. A solution that helps to recover energy in the blow line.

Reduction in boiler load

Maximum separation at any production level

Reduces total steam consumption in the system

Eliminates the need of fresh steam for pre-steaming

With Valmet Steam Separator PV it is possible to remove the need for fresh steam to the pre-steaming bin, and as a result reduce the total fresh steam consumption in the system up to 50%. In practice this means that it’s possible to reduce the need for fresh steam going to the Defibrator system and by that save the cost for producing steam that earlier was needed.

Case - cost savings with steam separator PV in Defibrator system

| Before | After | |

| Production | 30 bdmt/h | |

| Specific energy | 110 kWh/t | |

| Total fresh steam per ton fiber produced | 375 kg/bdmt | 224 kg/bdmt |

| Chip temperature after presteaming | 90-95°C | |

| Fresh steam usage for presteaming | 4,6 t/h | 0 t/h |

| Total fresh steam for system | 11,2 t/h | 6,7 t/h |

| Steam to dryer | 9,8 t/h |

4,8 t/h |

| Result |

~40% Total steam reduction ~400k€ Estimated cost savings per year* |

|

*Calculation based on selling electricity to the grid for 90 EUR/MWh

Read more

Our expertise is at your service

Our focus is to bring your performance forward utilizing our extensive experience and in-depth knowledge of pulp process technology. Get in touch with our experts through your local Valmet office, or the link below.

Contact us