Chip washing

Producing quality MDF requires chips that are as free from impurities as possible. Debarking and screening are not enough. Chip washing is essential for producing board of low mineral content. The growing use of purchased chips, e.g. from sawmills, results in an ever-increasing need for chip washing. Existing impurities, in the form of metal, stones and sand, must be removed before the chips enter the process.

Improved panel quality, less energy consumption, reduced machinery wear

Efficient chip washing increases the lifetime of refiner segments and reduces maintenance and replacement costs for other machinery in the process such as plug screws, preheater, feeder screws and other machinery. Efficient chip washing reduce the grit content in the finished panels and enables optimal consumption of chemicals, electricity and raw materials

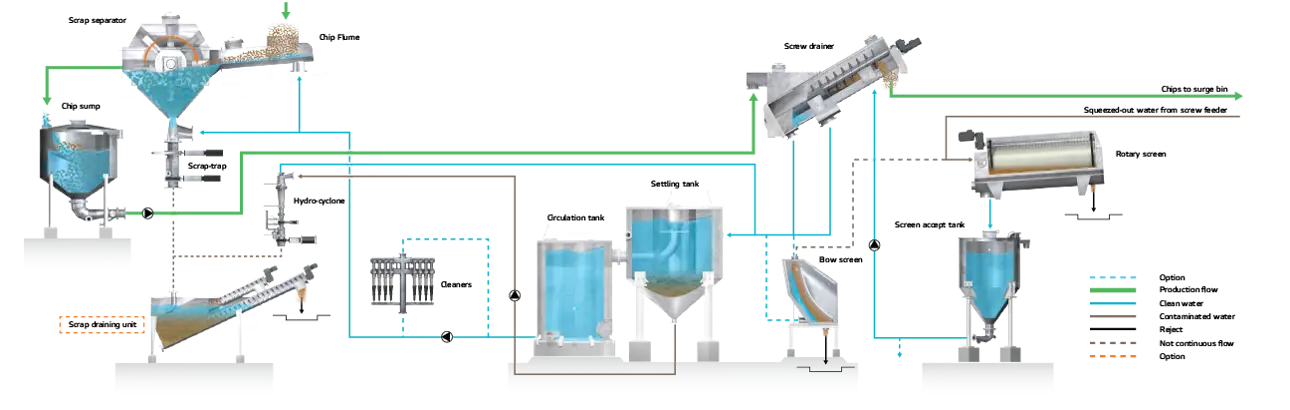

The raw material are mixed with water in the scrap separator which separates and removes foreign material like sand, stones and metal particles.

After the washing, the raw material are drained from water by a screw drainer.

The collected water is re-used at the chip washer. Excess waste water from the washer and plug screw feeder can be treated and re-used to make the needed steam in the fiber production process.

Valmet Chip Washing concept overview

Material available for download |

||

|---|---|---|

| Valmet Chip Washing | Scrap separator | Screw Drainer |

Our expertise is at your service

Our focus is to bring your performance forward utilizing our extensive experience and in-depth knowledge of pulp process technology. Get in touch with our experts through your local Valmet office, or the link below.

Contact us