Valmet to deliver automation to Tampereen Sähkölaitos Oy’s new Naistenlahti 3 boiler plant in Tampere, Finland

Valmet Oyj’s trade press release on April 20, 2021 at 11:00 a.m. EET

Valmet has received an order from Tampereen Sähkölaitos Oy for an automation system to the Naistenlahti 3 boiler plant, which is currently under construction in Tampere, Finland. In April 2020, Valmet announced the order of this biomass-fired boiler plant.

The automation order is included in Valmet’s orders received of the first quarter 2021. The value of the order will not be disclosed. The boiler plant with its automation solutions will be taken over by the customer in December 2022.

“Tampereen Sähkölaitos and Valmet have a long track record of excellent cooperation. We use Valmet DNA as our main automation system at many of our plants, for example, in Lielahti, Hervanta and Sarankulma. Also, our Naistenlahti power plants 1 and 2 are equipped with it. We value Valmet’s technology, integration with our existing systems and our long-term relationship,” says Antti-Jussi Halminen, Senior Vice President, Tampereen Sähkölaitos.

“I’m very happy that this automation delivery continues our good cooperation. Valmet’s boiler and automation system deliveries to the Naistenlahti boiler plant 3 support each other, leading to an optimal result,” says Arto Mäkinen, Sales Manager, Automation, Valmet.

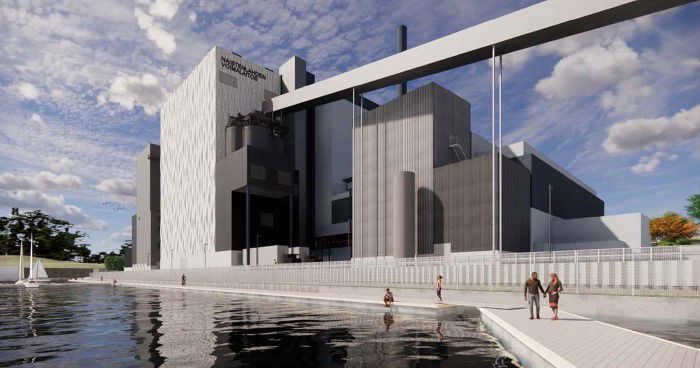

Valmet to deliver automation to Tampereen Sähkölaitos Oy’s new Naistenlahti 3 boiler plant in Tampere, Finland. (Illustrative image)

Technical information about the delivery

Valmet’s total scope of delivery includes a Valmet DNA Automation System, safety-related systems, Valmet DNA Machine Monitoring, Valmet Training Simulator, information management calculation applications for both emissions monitoring and reporting as well as monitoring the key performance indicators (KPI) of the boiler and the entire plant.

The automation system will be equipped with a Valmet DNA User Interface (DNA UI) that adapts the shown information based on the needs of various users and user groups. Relevant information is delivered in visual, well-structured, easy-to-understand dashboards, process and sub-process views, allowing the users of the automation system to control the process better. Built with the latest web technologies, DNA UI comes with a secure web-based access that enables the plant teams to access relevant information whenever they need it, regardless of their location.

The new boiler plant 3 will replace the existing boiler plant 2 and re-use some of its process parts, which all are already based on Valmet DNA.

About the customer

Tampereen Sähkölaitos Oy is a modern energy group that produces renewable energy and actively develops future energy solutions in Finland. Through its systematic development work, the company lowers CO2 emissions from its energy production and creates jobs for the surrounding area. In 2020, the group’s net sales amounted to EUR 265.1 million, and it employed nearly 400 professionals.

VALMET

Corporate Communications

For further information, please contact:

Arto Mäkinen, Sales Manager, Automation, Valmet, tel. +358 40 549 2330, arto.makinen@valmet.com

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com, www.twitter.com/valmetglobal