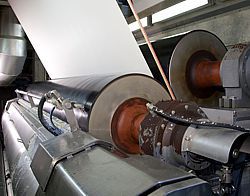

Five checks at shutdown when inspecting rubber covered rolls

Jun 28, 2022

- Uneven cover wear.

- Check for extreme temperature fluctuations across the covered face. Localized hot bands or isolated hot spots could indicate cover adhesion loss beginning in that area.

- Check for cracking. Cracks that show a general orientation parallel to the roll axis could indicate problems with the roll crown. Take a nip impression to check.

- Check for smash cracks. These typically are a concentration of multiple cracks occurring in small, very localized areas and are of random orientation with respect to each other and to the roll axis. Wads or other objects passing through the nip usually cause these cracks.

- Check for changes in cover appearance. This could be in the form of washouts; rough areas of wear, in grooved press rolls changes in groove dimensions and cupping around the holes of drilled press rolls.

For more information on roll cover maintenance, contact your Valmet representative.