White water opportunities for energy, fiber & water savings (webinar)

May 4, 2021

Most operating PMs have opportunities for cost savings via improvements in treatment and use of the excess white water from the forming and press sections. Two main opportunities are: energy savings by increased use of hot filtered water to replace fresh water for showers, and fiber savings from improved fiber recovery by the PM saveall to reduce sewer losses.

A webinar on Wednesday, May 12th, 2021 explained white water management and improvement possibilities. This webinar is also useful for mill personnel who work in another area of the mill and are unfamiliar with the white water process and water management, but wish to learn about them. The webinar is available for viewing HERE.

During the webinar, Jack Milliken, Valmet Product Manager, explained:

- the potential opportunities for cost savings with improvements to the white water system

- the questions to ask and data to obtain in order to identify and evaluate potential projects with strong ROI, and/or requirement for parts and services to improve performance of an existing white water saveall and shower water system

- what is paper machine excess white water

- what are the benefits of improved white water treatment

- how to develop a water management plan, including goals

- what process equipment is used to treat white water

- what are the best practices and how can Valmet help improve your white water process

Here is an example of what you will learn about savealls...

- basics of white water filtering

- function = save material, water and energy

- equipment = vacuum disc filter

- benefits of white water filtration

- monitoring saveall efficiency

- best practices to improve saveall efficiency

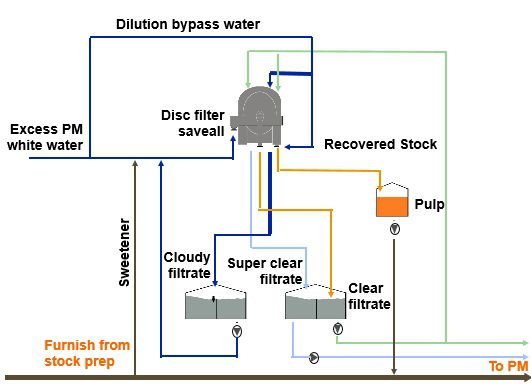

Typical paper machine saveall arrangement

Benefits of efficient saveall operation

Savings include:

- Energy savings from reduced water heating

- Material savings from reduced solids loss

- Water savings from recycle and reuse

- Wastewater treatment cost savings

Adequate and uniform consistency of recovered stock and broke returned to mixing tank means fewer wet end breaks, and faster recovery from breaks.

Consistent quality filtrate used for shower water means means reduced plugging of showers, improved saveall efficiency and less maintenance. Use clear filtrates for PM showers to save energy and water.

How to evaluate saveall efficiency?

Capacity should be adequate for excess PM white water and in some cases support broke thickening. Filtrate quality should be at benchmark ppm's or less. Recovered stock % consistency should be adequate (e.g. 4%) to support blend chest consistency control target with trim dilution.

If you have any questions about optimizing your white water usage and developing a water management plan, watch the webinar and contact your Valmet representative.