Boiler tuning best practices for efficiency (webinar)

Apr 20, 2021

Boiler tuning best practices for efficiency and emissions

Boiler tuning allows a recovery boiler to operate more efficiently. Key process components to recovery boiler operation are the combustion air system and the black liquor. With experience, you can make can make small changes to the boiler operation to optimize efficiency. These changes can improve reduction efficiency, lower emissions, and lower the ash carryover to reduce boiler plugging.

A webinar on Wednesday, April 28th, 2021 explained recovery boiler tuning and provided practical examples. Click HERE to view the webinar. This webinar is also useful for mill personnel who are not in the recovery area, but wish to learn what the recovery boiler process is and how it works.

During the webinar, Sarah Henke, Product Engineer for recovery boilers, explained:

- The purpose of boiler tuning

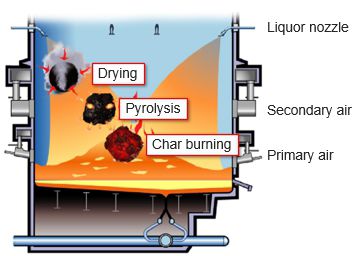

- What is black liquor combustion (drying, pyrolysis and char burning)

- The imortance of air distribution (primary, secondary, tertiary and quaternary air)

- Black liquor characteristics including the black liquor system

- How black liquor firing equipment affects liquor introduction into the boiler

- Operation and optimization tools (cameras, port rodders, gun cleaners, gun stations and nozzles)

Here is an example of what you can learn about black liquor combustion...

Black liquor combustion

Black liquor is sprayed into the lower furnace. For chemical recovery, chemical reduction of molten chemicals takes place under the char bed. All sulphur in black liquor and side streams is recovered as sodium sulfide (Na2S). Excess sodium is recovered as sodium carbonate (Na2CO3). Smelt is dissolved into green liquor. For heat recovery, the organic compounds are burned and high-pressure steam is generated.

Black liquor combustion process in the recovery boiler

Drying

In order for combustion to take place, the liquor droplet must be dry. This drying starts as soon as the droplet leaves the liquor nozzle. The heat for this drying is supplied from the combustion process and the radiant heat from the char bed. Factors affecting drying include droplet size, dry solids content and droplet distribution into the furnace.

Pyrolysis

During pyrolysis, the liquor droplet starts to expand. During this expansion, combustible gases are released from the liquor droplet. The combustion of the pyrolysis gases takes place at the secondary air level and higher. The heat from this combustion is used to dry the liquor droplet prior to it reaching the char bed.

Char burning

During char burning, enough heat is generated to melt the residue. It is important that all the char does not burn out prior to reaching the bed, as the reducing effect of the carbon is required to complete the sulfate to sulfide conversion in the bed.

If you have any questions about recovery boiler and liquor tuning, watch the webinar and contact your Valmet representative.