Coated board reel control rebuild reduces waste, case study

May 20, 2019

Tight market conditions prompted a mill manager to raise his hands in exasperation. He had essentially been doing the best job he knew possible with the equipment at his disposal, but it wasn’t enough. The coated board mill was facing 3 to 5 inches of bottom waste at the reel, and this was unacceptable.

A reel rebuild is proposed

Striving to reduce waste, the mill manager wondered whether a rebuild could achieve any satisfactory results. He asked a service technician to see if it was possible to decrease current waste levels, reduce the loading force of non-controlled variables, and gain better feedback control on the reel operation. Surprisingly, the technician said that a rebuild could not only achieve all these results, but it also would add some additional control to the reeling variables.

Analysis of the reel operation showed that the existing reel design was incapable of handling the current paper machine capacity. Moreover, the existing operation did not allow mill operators to control the variables needed to produce more high-quality, saleable coated board.

The rebuild scope

The first step in the rebuild process was to change the pneumatic system to hydraulics, which provides the mill with the ability to control roll building with accuracy. In the old system, operators faced a lack of accurate and repeatable control.

The rebuilder then installed a programmable logic controller (PLC) as the brain behind the rebuilt reel operation. The PLC sends a variable output signal to the directional proportional control valve circuits, providing proper parent roll loading, which is essential to control roll wound in density.

In the primary section of the reel, the rebuilder installed relieving levers, actuators and new clamps. This spool weight relieving system was a significant improvement in controlling density at the beginning of the roll building in the primary section. This allowed the mill to have a fixed clamping pressure, while only having a single variable relieving pressure.

The rebuild of the reel’s secondary section included the addition of hydraulic cylinders (connected to the existing arms) with closed loop feedback through the use of pressure transducers and position encoders. Operators can now input parameters for the reeling system using the HMI touch screen.

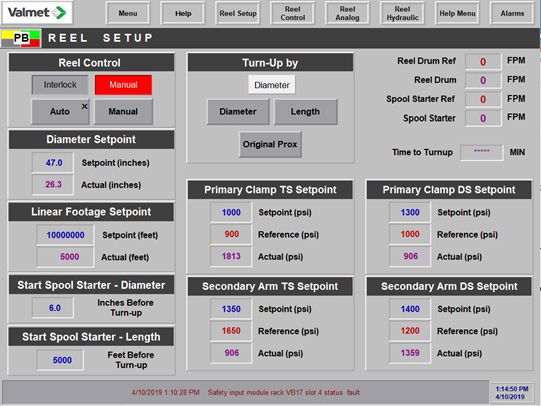

Example HMI screen for reel setup

The feedback on this operation is displayed on the HMI screens to show that these parameters are being met during reeling. Through the use of operator screens, software programming, proportional controls and the PLC, the mill has a closed loop feedback system that was not even considered in the pneumatic system.

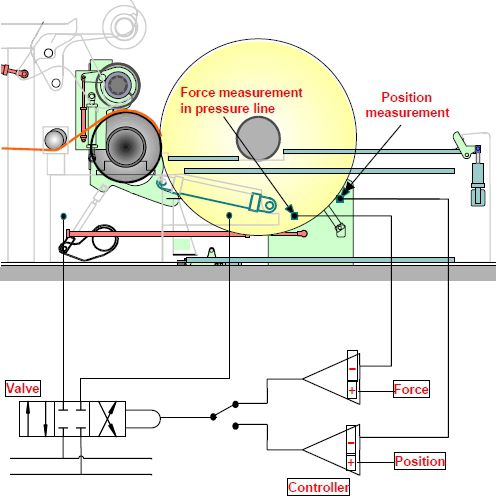

Schematic of reel position, nipload control and diameter indication with PID closed loop feedback

To put the closed loop feedback system to good use, the rebuilder created a bumpless transfer continuation to provide uniform loading during the primary to secondary transfer. During transfer, the primary arms reduce loading pressure as the secondary arms increase pressure. To compensate for the increases and decreases in mechanical limitation, the rebuild system uses the closed loop PID logic and hardware circuitry. In simple terms, the loading force is varied during roll building to maintain a constant pressure per linear inch.

Finally, the rebuilder provided automatic sequencing with manual override so that operators could input the required set/parent roll size and the reel would operate automatically.

Bottom waste reduced, better quality board

In assessing the rebuild, the mill manager felt that it was a success for two major reasons. First, the mill decreased its bottom waste to 1 inch from the 3-5 inches in the old reel setup. This meant an increase in the amount of saleable coated board. Second, the mill was able to reduce the loading force and obtain better control over winding variables. This resulted in a higher quality board.

Overall, the rebuild included the installation of new primary arms, clamps, and a spool weight relieving system. The addition of a new HMI system, PLCs, and software programs allowed operators to provide bumpless transfer between the primary and second reels.

Although the new hydraulic reel system looked entirely different than from the pneumatic system, the rebuilder reused the existing drum, doctor, and secondary arms and supports. And operators not only found the system more user friendly than the previous one, they also found it to be more productive.

For more information about reducing waste in your reeling operation, or any other reeling questions, contact your Valmet representative.