Explanation of size press edge wipe operation and proper setup

Nov 26, 2019

Edge wipes are used when running starch on SymSizers. No edge wipes are used when precoating on the sizer. Their purpose is to doctor off excess starch or lubrication water outside the sheet path.

If this water/starch is not removed, it will accumulate in the roll nip and cause spitting. Spitting can affect sheet quality if it gets onto the sheet as well as housekeeping and safety issues.

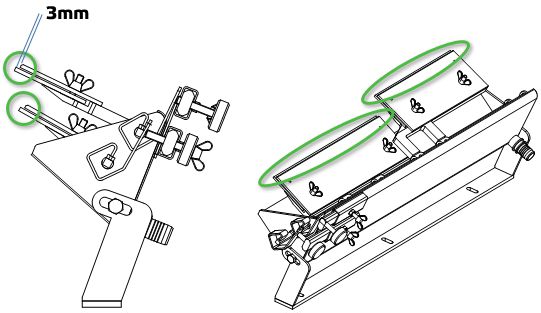

Wipe extends too far (left), wipe extends the correct amount (right)

The pictures above show two conditions of edge wipe setup. The one on the left shows its wipe extended from the holder by over 1”. For this setup, the wipe will bend when loaded and not doctor off the liquid that well.

The picture on the right shows a properly set up edge wipe. By only having about a 3mm stickout, the poly wipe will do a better job at removing the liquid. To doctor with such a small stickout, the holder must be located close to the roll – about 5 to 10mm clearance. This dimension is set with the applicator roll stopped for obvious reasons and always after a roll change.

Correct extension of wiper blade is 3mm from the holder.

The graphic above shows a double edge wipe assembly that is used on a ValSizer size press. The double wipes allow for a wider web width variation. In this instance, the double edge wipe blades are setup with a proper 3mm extension from the holder.

If you need any specifications on Valmet's recommended edge wipe material, your Valmet representative can get you the specs.