Understanding coating viscosity, rheograms and rheology problems

Jan 19, 2016

Coating rheology is measured with low shear (Brookfield) and high shear (Hercules) viscosity instruments. Viscosity is the resistance of a material to flow. Specifically, in coating rheology, it is the measure of the resistance of a coating formulation to an imposed flow.

Low-shear viscosity

Low-shear viscosity is the most often performed test in the control of the coating process. It is a simple test but very useful for determining operation of the coater. Brookfield viscosity is a good indication of coating solids, problems with the starch cooker operation, blade load pressure, coat weight control, and drying demand.

High-shear viscosity

High-shear viscosity is not usually done on the coater, but performed in the lab when testing different coating recipes or investigating coater runnability problems. It is a good indication of how the coating will respond to high shear rates under the blade tip. High high-shear viscosities can cause poor coat weight control, bleeding at the blade tip, and excessive blade loading, which can lead to poor runnability on the coater.

Coating rheograms

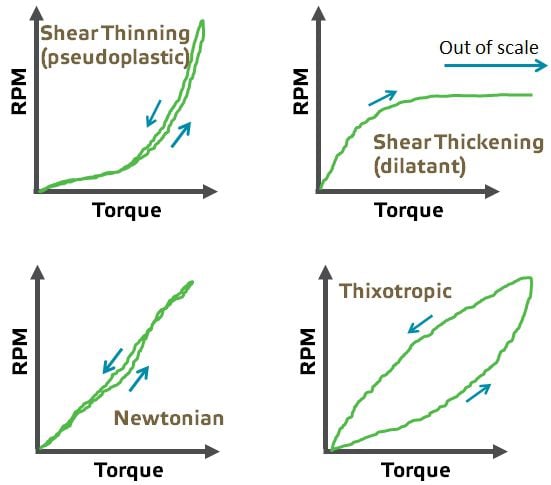

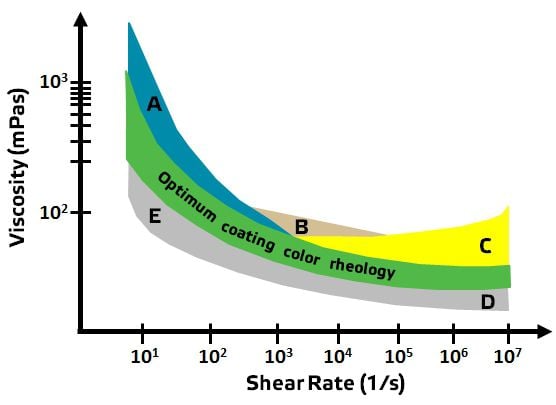

Figures 1 & 2 are illustrations showing how different types of coating recipes are affected by shear rate and the problems that can arise when viscosities get out of control.

Figure 1 Characteristic rheograms

Figure 2 General guidelines for interpreting graphs (see area descriptions below)

Table of rheology and associated problems

| Area | Rheology | Problem(s) |

| A | High viscosity at low shear rates | Pumping and startup problems |

| B | High viscosity at high shear rates | Problems in screens and applicators |

| C | High viscosity at ultra high shear rates |

Blade bleeding and streaking Problems maintaining target coat weight Web breaks |

| D | Low viscosity at ultra high shear rates | Uneven coat weight |

| E | Low viscosity at all shear rates | Water retention problems |

Coating recipes vary by mill, so we don’t have specific information on them. The best resource for mill coating information is the Technical Services department in most mills.

For more information on improving your coating process, contact your Valmet representative.