Safe and efficient calender roll removal - four methods

Feb 23, 2021

The following methods of calender roll removal are recommended by Valmet. Other methods may be used, depending on the style and size of calender and the lifting equipment available at the mill.

Before attempting to remove a roll, make certain that all air, steam, water and lubrication hoses are disconnected from the roll and outboard doctor.

Unbolt the outboard doctor and remove with the overhead crane. Place the doctor carefully on the floor supported by blocks at each end and with the holder pointed up.

Unload inboard doctors

If all the rolls of a calender stack are being removed, start at the top roll and remove one at a time. When removing one roll from within the stack, activate the roll lift unit and separate the rolls to the maximum. This will provide clearance for removal.

Roll removal

An overhead crane with two or three hooks is the recommended equipment for calender roll removal, As illustrated in the following procedures, the overhead crane may be attached to the roll with a roll removal lift bar, a sling around the journal or a sling around one end of the roll.

|

CAUTION: Regardless of how the crane is attached to the roll, the bolt (possibly 2) which attaches the bearing housing to the roll arm should not be removed until the roll is firmly held by the overhead crane. Do not remove bolts from a roll other than the one being held by the overhead crane. Rolls not supported by the crane could cause bodily injury to personnel working near the stack if accidentally bumped off the roll arm. |

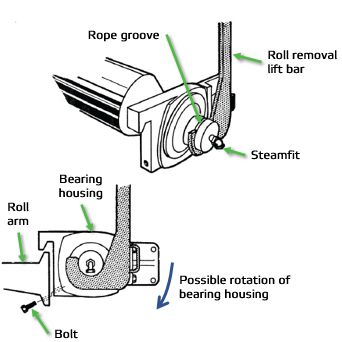

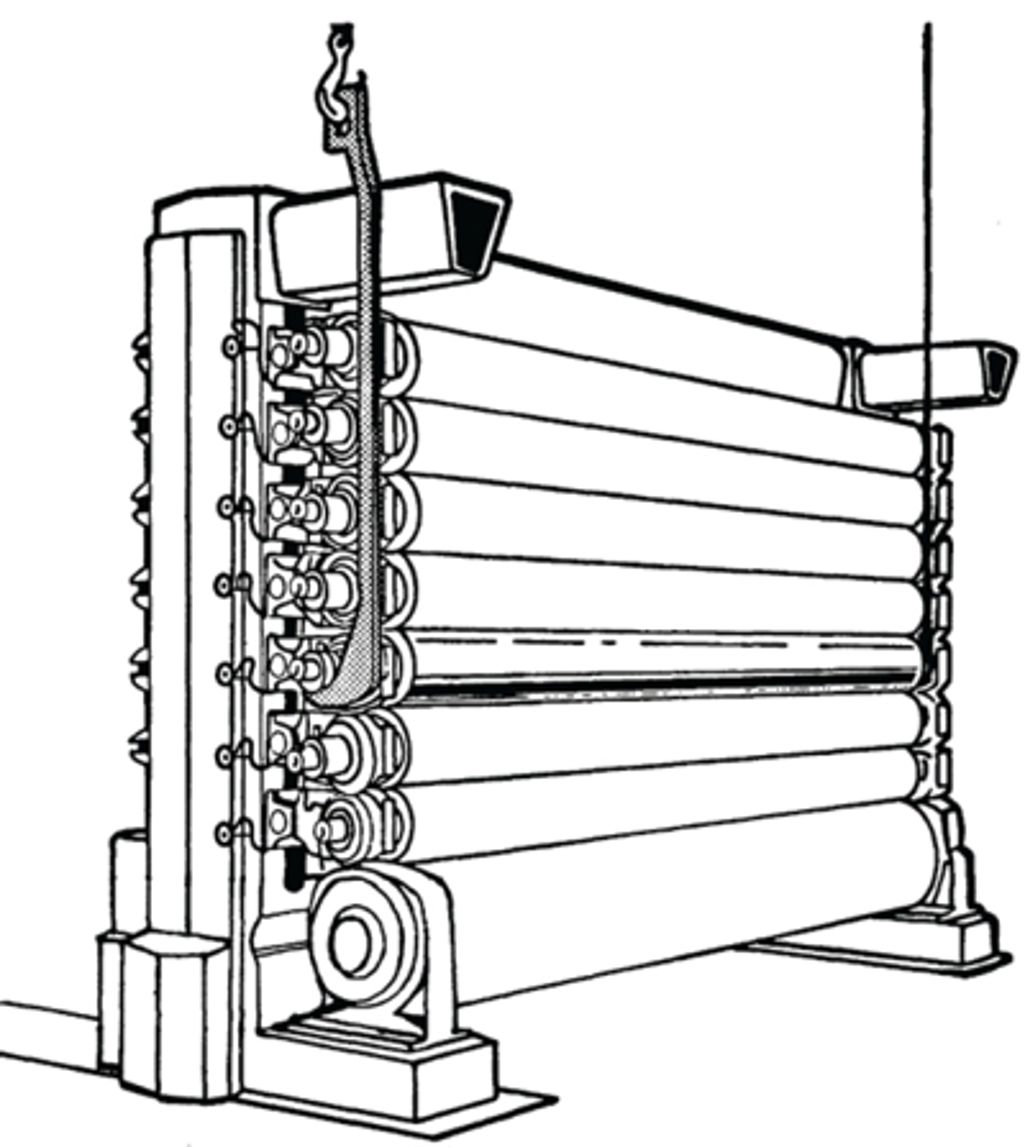

Secure the housing to the lift hook (Figure 1) or lift the roll slowly allowing the housing to rotate to a balanced position.

Figure 1 Roll removal details

|

CAUTION: The unbalanced weight of the calender bearing housing may cause bodily injury if allowed to rotate suddenly after being lifted out of the stack. |

Method one

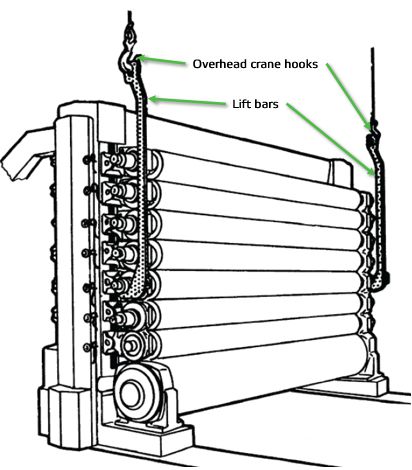

Figure 2 shows the calender roll being removed with roll removal lift bars. No overhead framing interferes with removal from the stack.

Figure 2 Roll removal lift bars

- Hook the roll removal lift bars into the roll handling grooves provided in the journals of the roll. Take up the weight of the roll.

- Remove the bolts attaching the bearing housings to the roll arms. Be very careful during handling to protect the roll face.

- If the doctor bracket is on the bearing housing, it will tend to rotate toward the outside. To avoid this, thread a bar and screw the threaded end into one of the mounting holes. Use this bar to steady the bearing housing during removal.

- Move the roll horizontally from its position until it is out of the stack.

- Move the roll away from the stack and place on prepared blocking.

Method two

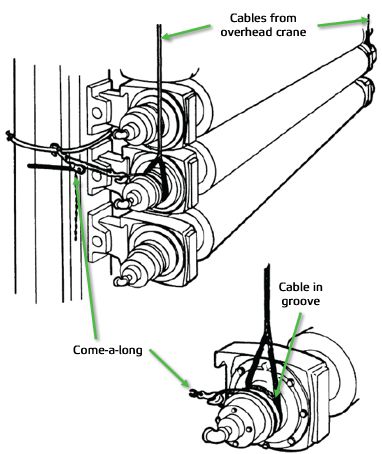

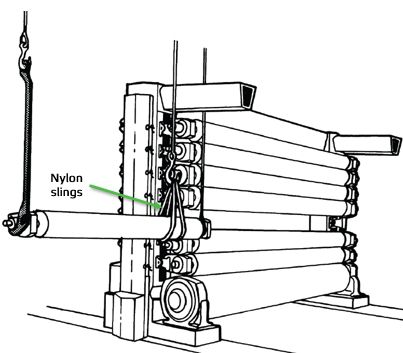

This method is an alternate which can be used on a calender stack as shown in Figure 2, Instead of roll removal lift bars, wire rope slings attached to an overhead crane and come-a-longs are used for lifting the roll.

Figure 3 Come-a-long with cables

- Position the wire rope slings in the roll handling grooves (Figure 3).

- Attach come-a-longs from the slings to the calender framing.

- Take up the weight of the roll and remove the bolts attaching the bearing housings to the roll arms.

- Move the overhead crane outward from the stack very slowly while working the come-a-long ratchet to move the roll from the stack horizontally.

- When the roll is out of the stack, remove the come-a-long units and continue moving the roll away from the stack.

- Place the roll on prepared blocking being very careful during removal to protect the roll face.

Method 3

Figure 4 illustrates a calender stack where overhead framing is present but is designed especially to allow rolls to be removed out and up from the stack. An overhead crane is attached to the roll as described in either method 1 or 2. The roll is lifted vertically out of the overhead framing and lowered onto prepared blocks.

Figure 4 Roll lifted inside overhead framing

Method 4

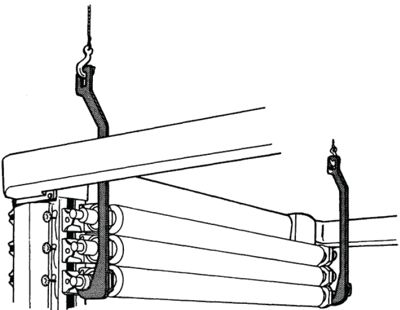

Figure 5 illustrates a calender stack in which the overhead framing prevents the roll from being removed from the stack in one operation. An overhead crane (or cranes) with three hooks is recommended for this removal operation.

Figure 5 Lifting inside and outside framing

- Attach the roll removal lift bar to one end of the roll while attaching a sling to the other end. The crane hook to the lifting bar will be on the outside of the overhead framing while the hook to the sling will be inside the overhead framing.

- Take up the weight of the roll and unbolt the bearing housings from the roll arms. Be very careful during removal to protect the roll face.

- Move the roll out of the calender stack and horizontally in the direction of the lift bar. (A come-a-long may be required on the sling side.)

- When the crane hook and the sling reach the inside of the overhead framing, use the third hook (Figure 6) and a sling around the roll (outside the overhead framing) to take up the weight from the first sling. Remove the first sling and continue removing the roll away from the stack.

- Lower the roll onto prepared blocking being careful to protect the roll face from scratches or damage of any kind.

Figure 6 Transferring roll to third hook

For more assistance with your calender operation and maintenance, contact your Valmet representative.