Doubled run time with Valmet Calender Roll Cover CL, case studies

Apr 29, 2015

Valmet Calender Roll Cover CL, Valmet's new composite cover, provides extremely high wear and barring resistance in physically demanding or barring-ridden calender positions. It provides paper and board makers with extended running time, resulting in signicant cost savings for every ton produced and trouble-free papermaking.

Extreme barring resistance

Barring is often a problem with on-line calender rolls. With Valmet Calender Roll Cover CL, material development has now taken a leap forward in barring resistance, including increased wear resistance, increased deformation resistance, plus a special base layer reduces cover shape deformation and roll vibration. Valmet Calender Roll Cover CL running time exceeds that of other covers in barring-ridden roll positions, and its barring resistance has been demonstrated on both multi-nip and soft calenders.

Doubled running times at Stora Enso Kvarnsveden

At Stora Enso Kvarnsveden's PM 12 in Sweden, high quality SC paper is produced with a modern 5 + 5 TwinLine multi-nip calender. After already achieving running times of about 800 hours with Valmet Calender Roll Cover CJ-W, the new Valmet Calender Roll Cover CL has nearly doubled that time, at almost 1,600 hours.

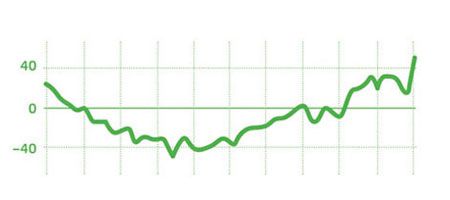

The cover profile after PM 12 TwinLine's running shows minimal uneven wear in the cross direction, despite aggravating factors such as high load, doctoring and abrasive SC paper. The diameter deviation of the scale is less than 100 µm.

The surface has remained very smooth throughout, even up to a Ra of 0.17 µm. Valmet Calender Roll Cover CL has managed this level of performance under harsh conditions: pressures of more than 400 kN/m and speeds of 1,130 m/min, while being doctored.

Håkan Kinnunen, Maintenance Manager at Stora Enso Kvarnsveden (on the left), and John Fridebring, Product Sales Manager at Valmet. "Good relationships come from good products that perform well, such as [Valmet Calender Roll Cover CL]," notes John Fridebring.

Anita Nordenström, Technician of the PM 12 TwinLine states: "With [Valmet Calender Roll Cover CL], we can run much longer without vibration." Longer running times have also given Maintenance Manager Håkan Kinnunen more flexibility in planning roll changes.

Long regrinding intervals

The new composite cover features high wear resistance, allowing for long regrinding intervals with predictable roll change times, less need for roll changes, and fewer regrindings. The latter lowers regrinding costs and extends cover lifetime. As a result, less wear in a cover translates into reduced maintenance costs and troublefree papermaking.

130 days and still running at North American mill

Valmet Calender Roll Cover CL extended running times are clear. A multinip calender at a North American SC paper mill achieved a running time in excess of 130 days at speeds of 1,170 m/min and a loading of 328 kN/m. This has been the longest run in this position without profile problems, according to the mill.

Excellent reliability

As calender covers are located in the physically most demanding positions in paper and board machines, they need to be durable. High-speed online calenders in particular pose a risk of cover failure, with web breaks causing very severe impacts on the cover. Valmet Calender Roll Cover CL sets a new standard in cover impact durability allowing for very high calender loads at a high nip frequency.

For more information on Valmet Calender Roll Cover CL or other Valmet roll covers, contact your Valmet representative.