Production of sulfuric acid from incineration of pulp mill NCGs

Mar 12, 2019

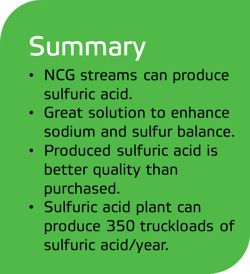

Sulfur is an essential chemical element in Kraft pulp mills and actively participates in reactions with wood chips to produce pulp. Sulfur is present in black/white liquors and discharge waters and escapes pulp mill processes as non-condensable gases (NCG). Traditionally, NCG are carefully collected and incinerated either in the recovery boiler / power boiler / lime kiln or separate NCG boiler. In many cases oxidized sulfur in flue gas is not recovered and thus increases the emission levels of the mill. To benefit all pulp mills, Valmet has developed sulfuric acid production technology from the incineration of NCG.

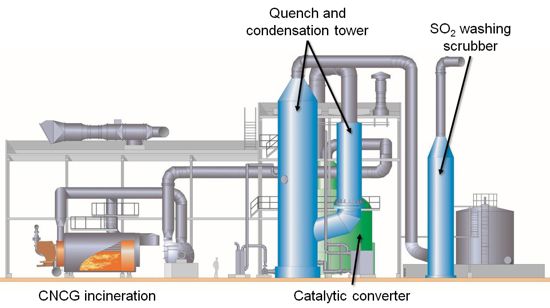

The sulfur dioxide produced from NCG incineration is oxidized to sulfur trioxide in a catalytic converter and condensed along with water vapor to yield sulfuric acid. The first sulfuric acid plant of this type started up in 2017 at Äänekoski, Finland and is in continuous operation. The internally produced sulfuric acid can replace purchased acid at several locations within the mill. A white paper located HERE describes production of sulfuric acid from NCG incineration, environmental advantages and closing the mill chemical balances with a sulfuric acid plant. This plant is one step closer to achieving the realization of future biorefinery concepts.

Sulfuric acid plant

To explore biorefinery opportunities for your pulp mill, contact your Valmet representative.