Trim ribbon conveying for a more efficient and safer process

Jun 28, 2016

The winder and reel of a paper machine are not often considered areas which need ventilation equipment of their own. Ventilation equipment is used in paper making mainly for drying (a hood, heat recovery, air dryers), for improving runnability, for keeping the wet end clean and, naturally, for maintaining a proper working environment in the machine hall. As regards the winder, paper running there is dry, clean and very strong when compared to the paper web running in the paper machine.

Trim ribbon conveying systems

However, ventilation equipment is needed at the winder or reel for several different purposes: dust removal, humidification, trim conveying and broke conveying. This article deals with trim ribbon conveying, for which Valmet provides three types of systems capable of conveying a range of ribbon widths from narrow up to a full butt roll width, thus potentially eliminating the need to create butt rolls:

- vacuum system

- trim ejector (or injector) system

- chopper trim conveying (to separator or pulper)

The remainder of the article will review the different methods of trim ribbon conveying, safety and applicable situations.

Trim conveying vacuum system

A narrow trim is cut from each edge of the full-width paper sheet at the winder or reel, to align the edges and to make the sheet width suitable for customer reels. The trims are sucked through trim nozzles from the cutting table to exhaust ducts, and led to a cyclone using a fan-created air flow. Centrifugal force separates the trims from the conveying air in the cyclone, and water jets drop them down to the pulper.

The conveying air flows away through ducts from the upper part of the cyclone to the fan and further out through a silencer ducted outside.

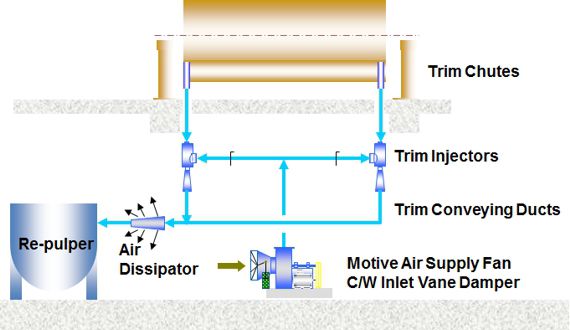

Trim conveying ejector system

The system consists of primary fan and ducts from the fan to the ejector, conveying / secondary ducts from the winder to the ejector, conveying ducts to the pulper, sound attenuators, and control dampers. Valmet delivers the trim chutes.

The trim is drawn from the slitter by suction. The required vacuum is produced indirectly by means of an ejector. The primary air for the ejector is supplied by a high-pressure fan. The airflow transports unbroken trim along the conveying ducts into the repulper.

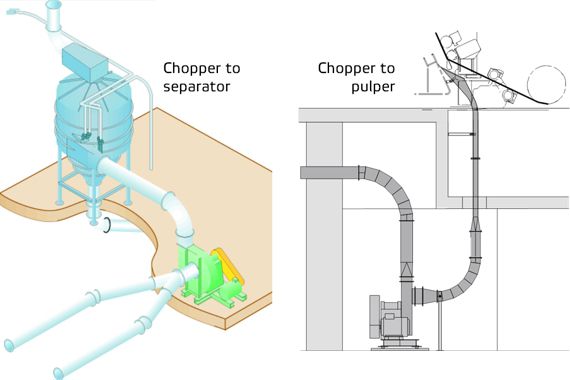

Trim conveying system, chopper fans

The system consists of chopper fan, ducts from the winder to the fan, and from the fan to the pulper, sound attenuators, and by-pass air damper. Valmet delivers the trim chutes.

The trims are drawn from the slitters by suction created by the chopper fan. Air volume is regulated by a by-pass air damper. The chopper fan chops or tears the trim into small pieces. The fragmented trim is then carried by the airflow along the ductwork into a repulper.

Safety is an issue with trim limitations

Valmet recently visited a mill in the southern USA because mill management needed to trim wider ribbons on their winders to satisfy their customer orders. But their current trim system could not handle these wider ribbons. As a result, the mill was required to make butt rolls. The butt rolls are tall and narrow, and recently a butt roll fell over and broke a worker's ankle. Thus installing a Valmet trim ribbon conveying system would both improve productivity and operator safety.

Valmet combines winder and air system expertise

The Valmet advantage over other air systems suppliers is our comprehensive knowledge of the winding process and how air systems interface with winder equipment. This expertise is especially useful when handling wider trim ribbons or speeding up the winder to trim more paper. An upgrade to the trim chutes or trim pans mounted on the trim slitters may be necessary.

Who should consider a trim conveying upgrade?

Mills that should think about a trim ribbon conveying system upgrade include board lines with older winders. Also some fine paper winders are being pushed to find more flexibility in their cut patterns, i.e. to maximize their overall sheet deckle. Their incoming customer roll orders are sometimes a very bad match for their deckle. In order to keep the customer, the mills end up running butt rolls, an unsafe and inefficient solution.

Overall benefits of a trim ribbon conveying system

- Eliminate safety risk of a butt roll falling over on a person.

- Eliminate a butt roll falling over and then the strain of getting it tipped back up.

- Eliminate handling of a butt roll - save personnel to perform other work

- Reduce operation costs by automating ribbon and butt roll handling.

- Less product through the winder will reduce wear on the winder.

Winder and reel air systems play an important role in the winding process by increasing production and improving both operator safety and the quality of the paper and board produced. Valmet has several references for these air systems, as well as decades of experience.

For more information on improving your trim and broke conveying, contact your Valmet representative.