New solution for making sulfuric acid - Sulfuric Acid Plant at the Äänekoski Bioproduct mill

May 9, 2018

Metsä Group contacted Valmet to develop a solution to make sulfuric acid from the mill's own chemical circulation to increase its self-sufficiency in chemicals.

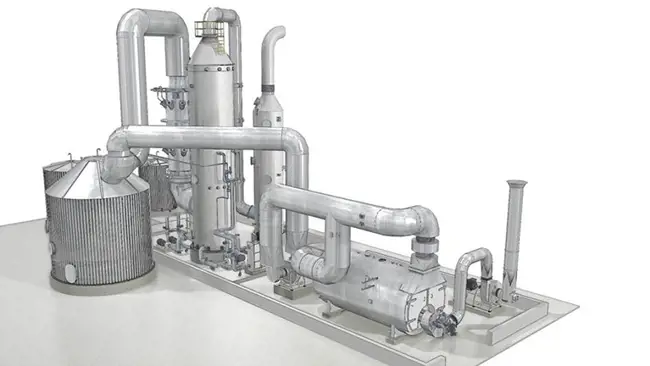

Valmet supplied a sulfuric acid plant to Metsä Group's bioproduct mill in Äänekoski for in-house sulfuric acid production. By means of the new sulfuric acid plant of its own the bioproduct mill can utilize the chemicals in the odorous gases of the pulp manufacturing process.

"The sulfuric acid plant producing process chemicals from sulfur compounds from odorous gases is a remarkable step towards closed chemical circulation and further improves the environmental performance of the bioproduct mill," says Timo Merikallio, Project Director at Metsä Group.

This project is an excellent example how Valmet is able to develop new innovative technology to meet customer needs.

"We had not done any internal R&D before we got the first query from Metsä Group. I am proud to say that we developed the solution literally from scratch and were able to deliver new technology within the normal project schedule," tells Eevi Smolander, manager for Valmet's mill wide NCG solutions.

Eevi Smolander from Valmet and Timo Merikallio from Metsä Group

In normal closed chemical circulation, the odorous gases are burned and recycled. Valmet delivered a technological solution that processes the odorous gases into sulfuric acid. The main challenge was to find the correct materials that are in contact with the 60–70 percent strong acid. Usually, sulfuric acid plants manufacture close to 100 percent strong acid, which is easier to handle and transport.

"So far the performance has been good. The technology works. The eye is now on the durability of the materials that are in contact with the sulfuric acid," says Merikallio.

The sulfuric acid plant is in conjunction with the odorous gas burner and can be run separately or simultaneously with the gas burner.

Key technology from Valmet to next generation bioproduct mill

The sulfuric acid plant delivery was part of Valmet's key technology delivery to Metsä Group's Bioproduct mill. Valmet's delivery to the mill included a recovery boiler, pulp drying line, gasification plant, lime kiln, sulfuric acid plant, and mill-wide Valmet DNA automation system.

All the equipment delivered by Valmet represent the latest technology and are highly energy-efficient. The gasification technology and recovery boiler will maximize the use of bioenergy and make the pulp mill totally fossil fuel-free. The recovery boiler, pulp drying line and lime kiln are the largest in Europe.