New way to save bulk in board-making

Apr 24, 2017

Valmet’s recently developed Aqua cooling calendering is an interesting approach to saving on bulk. The method is based on the fact that pilot calendering trials usually give a better bulk to surface smoothness ratio than results from an operational mill. The reason for this is that the paper or board web is colder in the pilot machine and hotter under actual mill conditions.

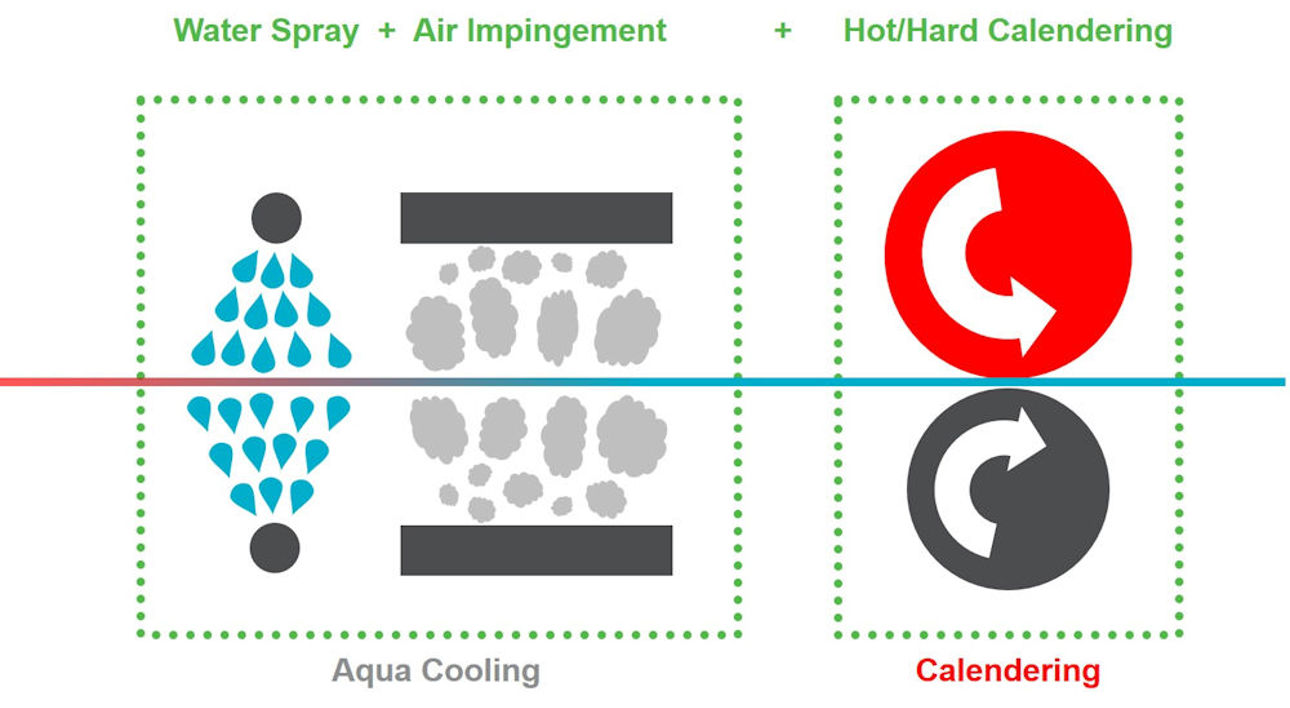

Aqua cooling calendering

Valmet’s recently developed Aqua cooling calendering is an interesting approach to saving on bulk. The method is based on the fact that pilot calendering trials usually give a better bulk to surface smoothness ratio than results from an operational mill. The reason for this is that the paper or board web is colder in the pilot machine and hotter under actual mill conditions.

Aqua cooling calendering recreates the ideal pilot conditions at the paper mill by cooling the web before calendering. This effective cooling is done by applying a small amount of water to the hot paper web and immediately evaporating the water by blowing cool, dry air over it.

Raw material savings of 2–4%

When water is applied to a paper surface, the wetting delay time tells you how long it takes before the water starts to penetrate the paper. With Aqua cooling calendering, the cooling takes place within the wetting delay time, so there is no roughening of the paper surface and no fiber-to-fiber bonds are broken.

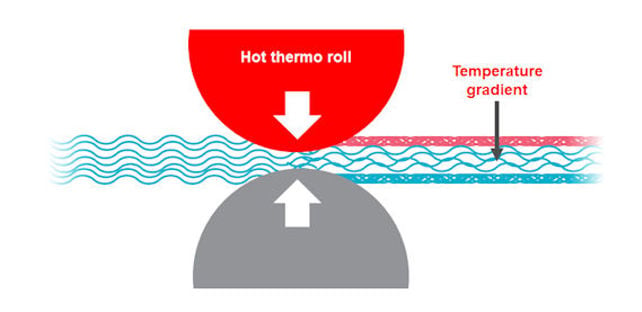

As the pilot trials confirmed, the entire thickness of the web is cooled, not just the surface. Since the calendering nip only heats the surface, the calendering effect is permanent only in the very top layers of the web. The inner layers are elastically recovered, and the bulk is saved. By preserving bulk, it is possible to achieve savings of 2–4% on raw materials.

Calendering effect: the web surface undergoes thermoplastic deformation. The inner parts of the web maintain their elasticity and bulk by sustaining the lower temperature.

Equipment is easy to use

The equipment for Aqua cooling calendering is suitable for both new paper and board machines and rebuilds. The OptiDry Chill aqua cooler unit used for blowing cool, dry air is a lot smaller in size than traditional air drying units,making Aqua cooling calendering ideal for rebuilds.

The equipment is very easy to use and maintain. “Apart from normal cleaning, we have not had to do any maintenance on the equipment in the year that it’s been in operation. There has been some normal work with the fans and motors, though,” concludes Stora Enso’s Production Manager Antti Veitola.