Lime kiln camera helps Stora Enso Oulu Mill to see the flame

Mar 14, 2022

A new lime kiln rebuild, part of a recent extensive paper machine grade conversion at the Stora Enso Oulu Mill in Finland, included a Valmet Visible Thermal Imaging System.

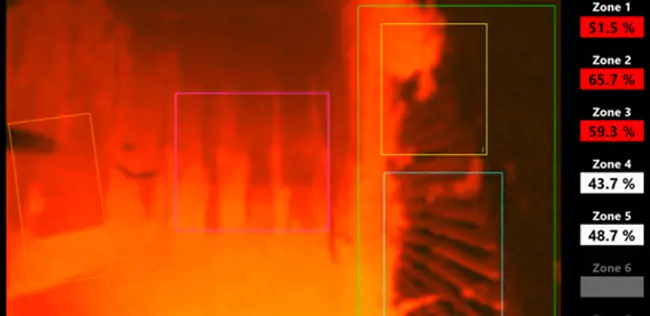

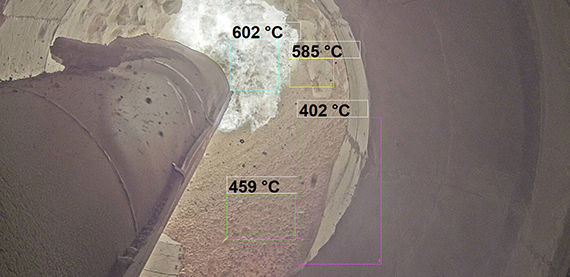

Consisting of a rugged, high-definition camera paired with a high-resolution thermal sensor, the system enables operators to continuously monitor flame shape and size as well as kiln temperatures during startup and operation of the kiln.

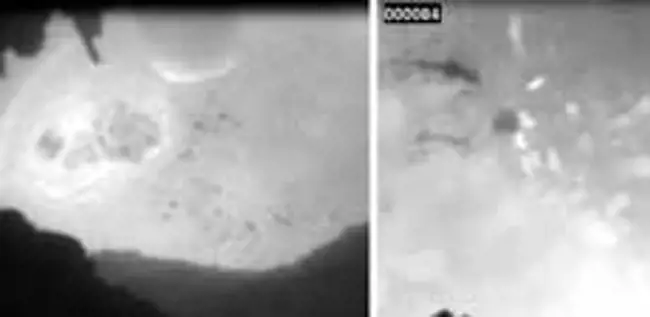

High dynamic range imaging

“We had a camera system in the old kiln,” says Kai Jalander, Production Engineer, “but we could only see some kind of flame and that was all! When we saw the videos from Valmet references, we were excited about the possibilities and the buying decision was immediately made. We compared at least one other camera system but overall Valmet was the most cost effective."

Designed for comprehensive observation and analysis in kiln environments, the Valmet Visible Thermal Imaging System provides unparalleled image quality from startup to full load conditions. The visible light camera utilizes three different shutter speeds to artificially expand the dynamic range and view the bright flame as well as darker areas in kiln.

The biggest advantage with the camera system is in seeing the lime dust especially when restarting from an unplanned shutdown.

Real-time monitoring

“The biggest advantage with the camera system is in seeing the lime dust especially when restarting from an unplanned shutdown. Then there can be a lot of dust which confuses the flame detection system. With the Valmet system we can really see what the problem is and that is a really big plus. The operators have a dedicated big screen display to see the quality of the flame and monitor temperatures in real-time and we can also look back with stored video if we have had a problem which helps trouble shooting considerably,” says Jalander.

Easier problem solving

“During a recent startup, after changing the burner, we saw the temperature of kiln surface was 20 degrees Celsius higher than normal. This was puzzling until we looked at the camera image which showed the flame shooting higher than before. Further investigation determined that the burner had been assembled incorrectly. With some adjustment, the camera confirmed the correct flame direction and the temperatures went back to normal. This was a really good example of the value of the camera,” affirms Jalander.

The Valmet Visible Thermal Imaging System had a trouble-free startup in January 2021. “Over the past year it has worked really well without any regular maintenance other than occasional cleaning. It certainly met expectations,” concludes Jalander.

Real-time camera image from Valmet Visible Thermal Imaging System

Related articles