More efficiency and runnability with new OptiPress Center

Oct 12, 2016

Modular design made the press section rebuild of paper machine PM 5 at Mondi’s Štêtí mill in the Czech Republic very easy. The schedule for the commissioning and start-up was only one week, and after the start-up, the mill had sellable sack kraft paper in just three days. With increased dryness resulting in better web runnability and less steam consumption, it is no wonder that the mill is happy with the OptiPress concept and co-operation with Valmet.

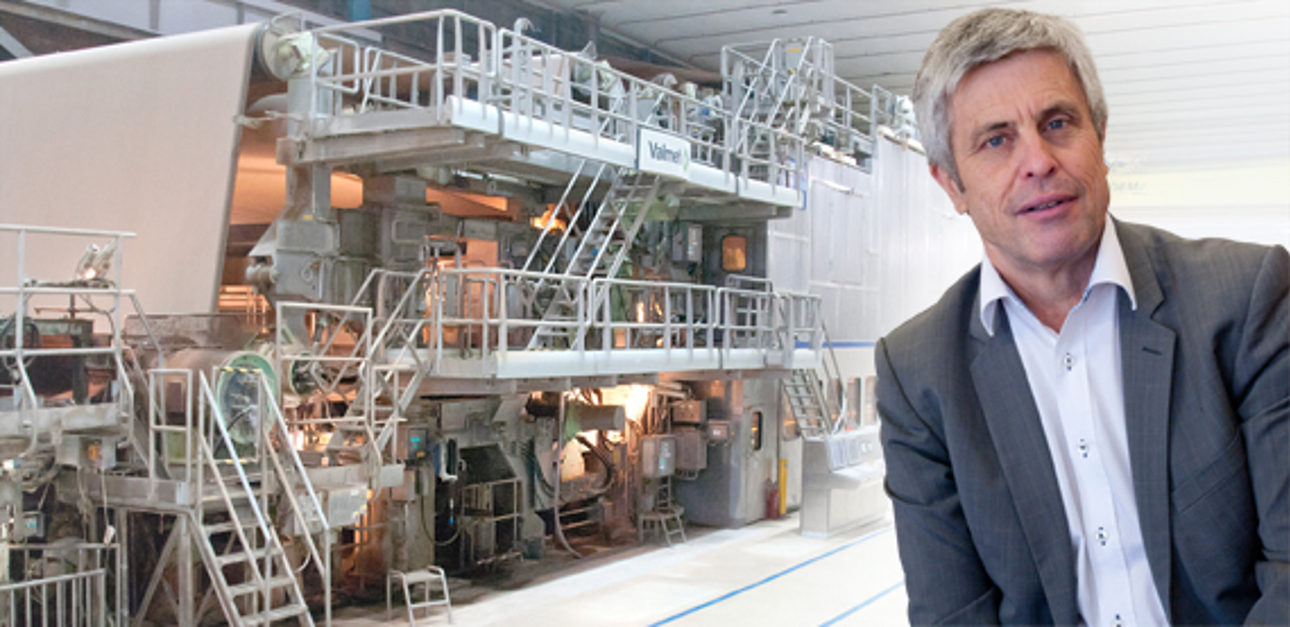

“Our old press section was no longer state-of-the-art”, tells Helmut Riesenberger, Senior Project Director at Mondi Štêtí. “The aim of the modernization was to reduce energy consumption and improve paper web runnability.” After considering all aspects, the mill took the bold step of having a total rebuild of the press section without reusing any existing press parts. The start-up was in October 2015.

Minimized shutdown

Minimizing the time needed for shutdown makes rebuilds more effective and affects the overall profitability of the project. Mondi and Valmet worked together in order to make the rebuild – and especially the commissioning phase – as efficient as possible. “The press section was preassembled in Finland for a very fast assembly phase here on site. The modular design with no cantilever beams meant that we had to put much less efforts on civil works. This meant lower costs as well, and we were on schedule from the very first day to the start-up,” Riesenberger recalls.

Besides the technology, Valmet also integrated the machine control system for the new press section into the existing automation system. Riesenberger sees the benefits of having a one responsible supplier for both automation and technology. “It is an advantage. Of course, we could solve this differently, but I think this is the fastest solution. Especially in rebuilds, where time is limited, this is a reasonable solution as the machine supplier knows best how to operate the system.”

The new system makes diagnostics and troubleshooting very easy. “Valmet’s machine control system (MCS) for the press section is fully integrated into existing distributed control system (DCS), so we can maintain this system and get all the data and values whenever we need in the future as well,” Riesenberger adds.

Improved dryness and runnability

When asked about the performance of the new OptiPress press section, Riesenberger’s answers promptly: “The key is the dry content, of course. The higher the dry content, the higher the runnability. The dryness values are now higher than before the rebuild. “It gives us a huge benefit in steam, as we have been able to reduce steam consumption enormously,” he says. Vacuum usage is at the same level as before, even with the increased production. Also, the number of sheet breaks was reduced significantly.

“All the efficiency figures, like time, material and speed, have improved compared to the values we had before the rebuild,” Riesenberger concludes.

|

“The configuration and the basic design of the press section gives us better profiles, even at higher speeds, which we really did not expect. We’ve had very good numbers from the first day.”

Helmut Riesenberger, Senior Project Director at Mondi Štêtí |

Quality improvement with better profiles

Brown sack kraft paper produced at PM 5 must meet the needs of demanding end customers. The best possible strength and stiffness are needed, as the sacks need to withstand rough handling and tough weather. Excellent runnability is needed for efficient converting and quick filling, and excellent printability to satisfy the demands from their customers.

“The configuration and the basic design of the press section gives us better profiles, even at higher speeds, which we really did not expect. We’ve had very good numbers from the first day,” Riesenberger explains. He continues: “The biggest benefit of the new concept is the absence of free draw between the nips. This fact has a positive effect on paper properties like tensile strength and stretch. Thanks to the higher outlet dryness, we were able to improve the ‘smile’ effect on the stretch CD, a means to lower the difference between the center reel and edge reels. Also, though we have a much higher dry content (higher press loads), we still can keep our porosity values, which are important for sack paper. We actually expected somewhat lower values, but they remained unchanged – we still have the same values.”

Perfect co-operation

Complex projects like this never succeed without good co-operation. “I really felt supported by Valmet, right from the very first day. They reacted, they listened to us, and we had open discussions on all topics. We also had differences of opinion, but in the end, we always reached a common view and a vision of how to proceed,” Riesenberger says. “This project was very systematic. This approach, to have certain standards, is also something that I like very much about Valmet.

The power of co-operation can be seen in the smooth start-up. “We met all our parameters for sellable paper at full speed in just three days”, Riesenberger

sums up.